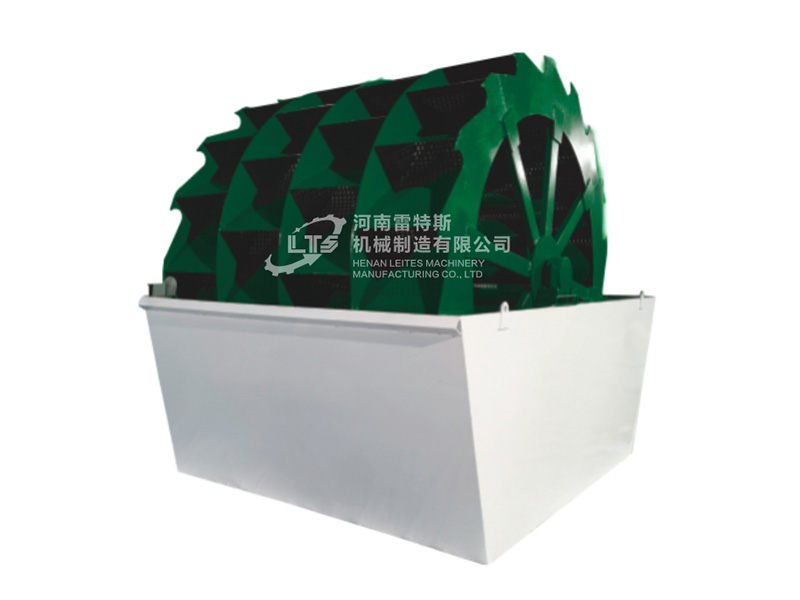

The XSD series sand washing machine adopts advanced technology at home and abroad, and is developed and produced in conjunction with the actual situation of the domestic sand and gravel industry. It is an efficient wheel bucket sand washing equipment used in conjunction with sand making machines. It has the characteristics of high cleanliness, reasonable structure, large processing capacity, low power consumption, less sand loss, and low faults. It is an upgraded product of domestic sand washing equipment.

When working, the motor drives the impeller to rotate slowly after decelerating through the triangle belt, reducer and gear, and the sand and gravel enter the washing tank, roll under the drive of the impeller, and grind each other to remove the impurities covering the surface of the sand and gravel, and destroy the water vapor layer covering the sand and sand, so as to facilitate dehydration; At the same time, water is added to form a strong water flow, and impurities and foreign bodies with small gravity are taken away in time, and discharged from the overflow outlet washing tank to complete the cleaning effect. The clean sand is taken away by the blade, and finally the sand is poured into the discharge tank from the rotating impeller to complete the cleaning of the sand.

1, the machine structure is simple, impeller drive bearing device and water and water material isolation greatly avoid the bearing due to water immersion, sand and pollutants caused damage phenomenon.

2, no pollution, high cleanliness.

3,Save water.

4, the machine has almost no wearing parts except the screen.

5, long service life, easy maintenance.

It is widely used in metallurgy, building materials, hydropower and other industries of washing, grading, impurity removal and other operations, suitable for fine particle size and coarse particle size material washing operations. It is suitable for construction sand and road sand. The sand washing machine has reasonable structure, convenient maintenance, large processing capacity, small power consumption and high cleaning degree. The novel sealing structure, the fully enclosed oil-bath transmission device, and the adjustable overflow weir plate ensure that the series of products are efficient and durable, the cleaning and dehydration effect is good, and the fine grain products remain stable.

| Model |

Reel diameters (mm) |

Feed-in size (mm) |

Capacity (t/h) |

Motor type |

Power (kw) |

Weight |

Dimensions(LxWxH) (mm) |

| XSD2610 | 2600 | ≤10 | 20-50 | Y160L-8 | 7.5 | 2.68 | 3321x2312x2683 |

| XSD2816 | 2800 | ≤10 | 30-70 | Y180L-8 | 15 | 5.3 | 3810x2820x2883 |

| XSD3016 | 3000 | ≤10 | 50-100 | Y200L-8 | 15 | 6.5 | 3830x2972x3200 |

| XSD3620 | 3600 | ≤10 | 80-150 | Y255S-8 | 18.5 | 9.8 | 4456x3479x3688 |

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

+8615713843888

+8615713843888

+8615713843888

+8615713843888