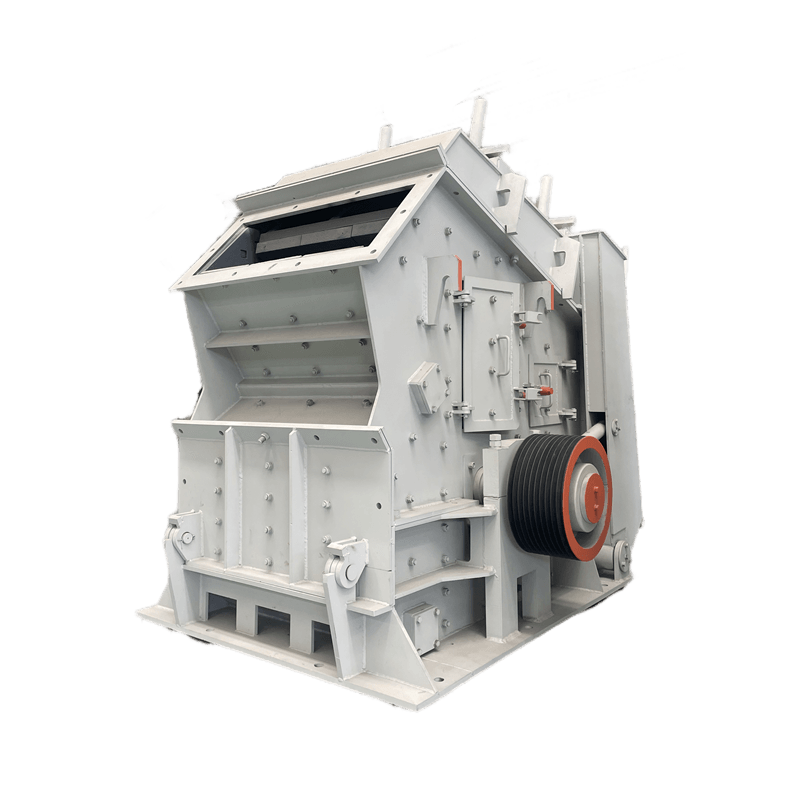

Jaw crusher and impact crusher are commonly used equipment in the crushing market, but many people do not particularly understand these two crusher equipment, especially friends who are new to the industry. For the difference between the two crusher equipment many users are also very confused, today we talk about the difference between the jaw crusher and the impact crusher.

The scope of application of the crusher is different

1, material hardness

Jaw crusher can break soft and hard materials, compressive strength between 320Mpa, and the impact crusher is suitable for breaking hardness and toughness of the following small, brittle materials, such as limestone, limestone, etc., if the material is hard, it will cause great damage to the wearing parts, thereby shortening its service life.

2, material particle size

Jaw crusher is generally used for crushing large materials, can allow less than 1m ore into (depending on the equipment model and manufacturer), the mine and gravel field application is more, the impact crusher is more used to deal with some small and medium-sized materials, the allowed feed particle size range is not as wide as the jaw crusher.

Second, the crusher production line location is different

As we all know, in the crushing, sand making, mineral processing and other production lines, the jaw crusher is the commonly used primary crushing equipment, used as coarse crushing (fine jaw breaking can be used for medium or fine crushing), and the impact crusher is the commonly used secondary or tertiary crushing equipment, used as medium or fine crushing.

Three, crusher production capacity is different

Overall, the capacity of the jaw crusher is greater than that of the impact crusher. In general, the output per hour of the jaw crusher can reach 50-1200t or so (depending on the manufacturer and product model), and the output per hour of the impact crusher is about 55-750t.

Fourth, the discharge fineness of the crusher is different

Jaw crusher as a coarse break, its discharge fineness is larger, generally below 300mm (depending on the manufacturer and product model), impact crusher as a medium break or fine break, the discharge fineness is of course smaller. It should be noted that due to different material properties, the discharge fineness of the crusher equipment will also have errors.

Five, crusher discharging granule type is different

The material size after extrusion treatment by jaw crusher is not ideal, and the needle content is too much. The impact crusher is a product with good discharge grain type and less finished product edges and corners in the crushing equipment, and its grain type is also better than the cone crusher. Therefore, in the actual production, the jaw crusher is usually configured after the impact crusher for further shaping, and the two are also more common in the crushing production line.

Six, the price of the crusher is different

In general, many manufacturers of jaw crusher and impact crusher sales are higher, the main reason is the price of the problem. Secondly, jaw crusher and impact crusher are more traditional crushing equipment, and can meet the application requirements of users in terms of performance, quality, power consumption, etc., so cost-effective equipment is easier to attract users’ attention.

As a large mining machinery and equipment manufacturers and suppliers, has a wealth of crusher manufacturing experience, machine quality is good, high efficiency, complete variety, in the market is very popular with investors, if you want to know more about the crusher information, welcome to call or online consultation, message, Leitos machinery will send professionals to answer your questions.

+8615713843888

+8615713843888

+8615713843888

+8615713843888