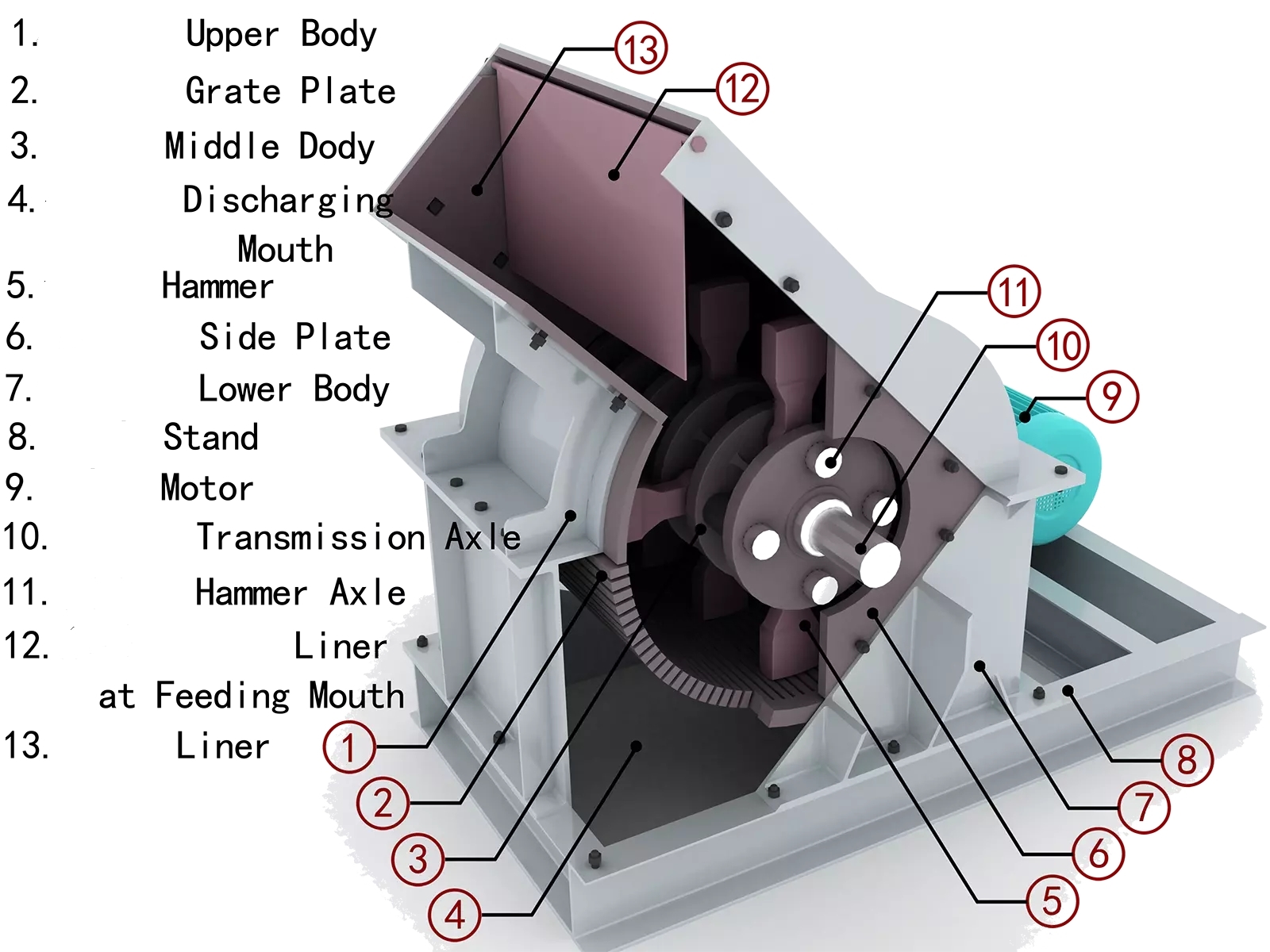

Compound crusher is a kind of non-screen bar, adjustable crushing equipment, can be widely used in cement plant raw material, clinker crushing operation, but also can be used in dolomite, coke gems, lead zinc ore, serpentine, blast furnace slag, coal gangue, phosphate rock and other medium hardness material crushing operation. Especially suitable for hard limestone, dolomite, granite, basalt and other artificial sand or highway pavement stone processing and crushing. However, in the process of long-term use, there will be some failures in the compound crushing, in order to prevent them from happening, in daily use, we should do a good job of comprehensive maintenance of the machine and equipment. The following will introduce you in detail:

Compound crusher

- Daily inspection

The daily inspection of the compound crusher mainly refers to the inspection work before opening and running. Before starting, the staff need to carry out a comprehensive inspection of the equipment, the inspection content includes the wear condition of the parts, whether the bearing lubrication is good, whether the fasteners or bolts are loose, whether the discharge particle size of the machine and equipment is uniform, whether there is abnormal vibration inside the cylinder and whether the temperature rise of the compound crusher is normal.

2, lubrication work

The high-efficiency production work of the compound crusher is inseparable from the good lubrication effect of the equipment, and the machine and equipment need to add lubricating oil to the bearing before starting. There should be no impurities or other debris in the lubricating oil, bearing oil injection need to be injected with oil grab half of the solvent in the entire space, the oil is too full, the oil is easy to overflow. The crusher should detect the temperature of the lubricating oil during operation, if the oil temperature is too high, it should be stopped in time to avoid burning the machine.

3, cleaning, cleaning

Because the compound crusher is used for fine materials, it is inevitable to produce a lot of dust in the production, and if too much dust accumulates, it will affect the normal production of the machine. Therefore, the operator needs to carry out regular cleaning or cleaning work. The parts to be cleaned in the compound crusher are rotor bearings, hydraulic systems, crushing chamber walls and other parts that are easy to accumulate dust.

This article mainly introduces the daily maintenance work of the compound crusher, hoping to help you. If you want to know more about the crusher, welcome to call or online consultation, message, Leitos machinery will send professionals to answer your questions.

+8615713843888

+8615713843888

+8615713843888

+8615713843888