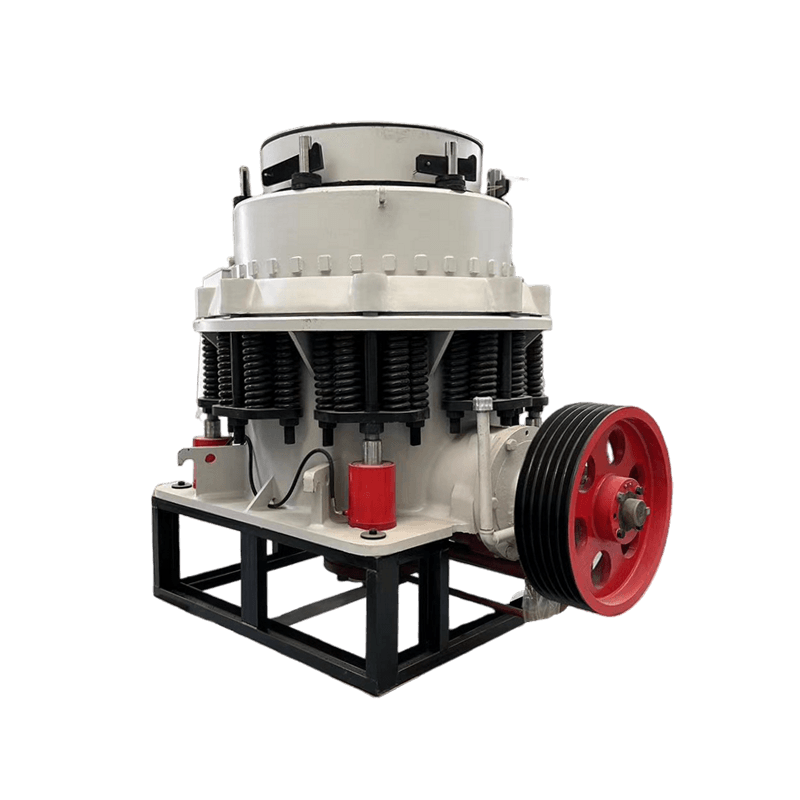

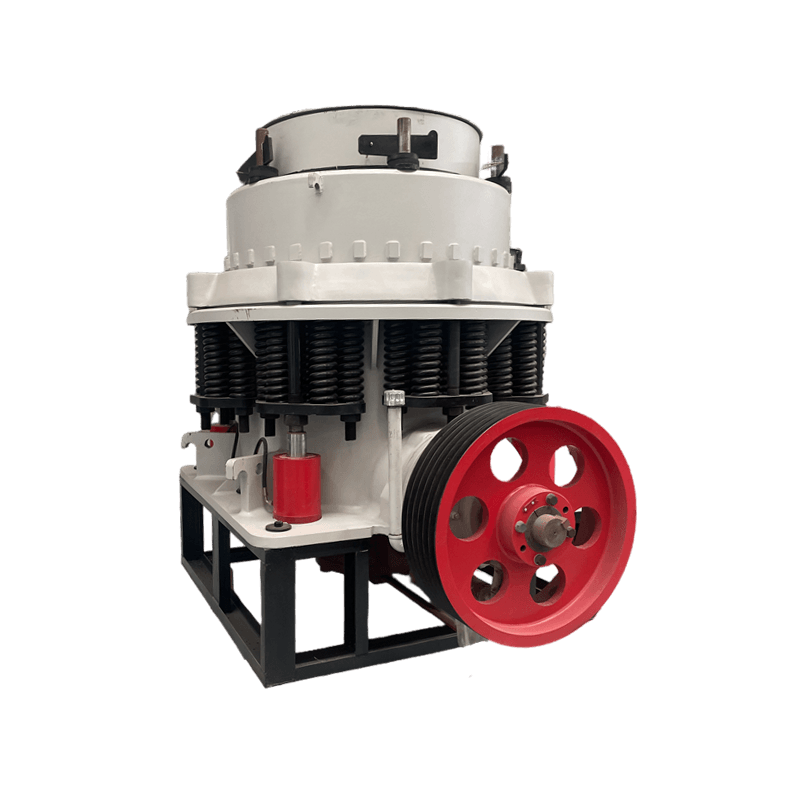

Cone crusher is a common type of crusher, also known as cone crusher. It is a kind of material crushing equipment mainly used for medium hardness and above medium hardness.

The working principle of the cone crusher is to use a conical crushing chamber and a rotating cone to break the material. The cone is fixed in the crushing chamber and driven by an electric motor to make the cone rotate. After the material enters the crushing chamber, it is crushed and squeezed by the cone, so as to break into the required particles.

Cone crusher has the following characteristics and advantages:

- Uniform particle size: Because the cone crusher adopts the principle of lamination crushing, the material is squeezed and milled several times in the crushing chamber, which can achieve better crushing effect and more uniform particle distribution.

2, fine crushing effect is good: cone crusher is suitable for medium hardness and above medium hardness of the material crushing, can be broken into finer particles.

- Lower energy consumption: Compared with other types of crushers, cone crushers have lower energy consumption in the crushing process, which helps to save energy and reduce production costs.

- Wide adjustment range: By adjusting the gap of the crushing chamber and the position of the cone, the discharge particle size can be adjusted to meet the requirements of different particle size.

- Strong adaptability: cone crusher is suitable for a variety of materials, including limestone, gypsum, coal, ore, etc., widely used in mining, metallurgy, building materials and other industries.

It should be noted that the structure of the cone crusher is relatively complex, and the maintenance and repair are relatively cumbersome. When selecting and using cone crusher, it is necessary to consider the hardness, humidity, particle size requirements and production capacity of the material to ensure that it can meet the production needs.

+8615713843888

+8615713843888

+8615713843888

+8615713843888