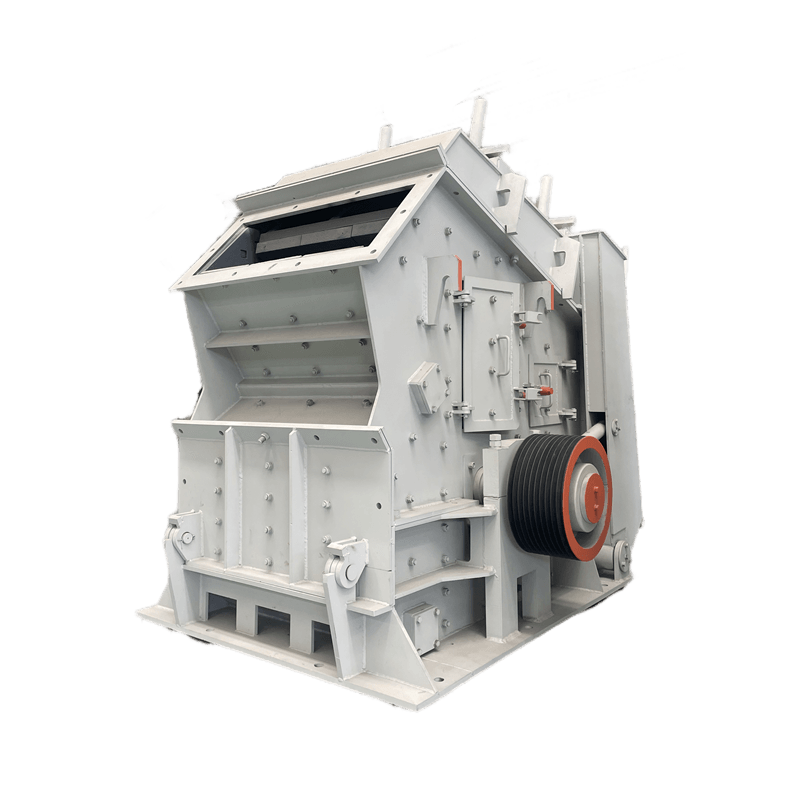

The impact crusher is a two-stage crushing equipment commonly used in the crushing production line of sand and stone materials, with simple structure, high crushing efficiency and shaping effect. The plate hammer is the core component of the impact crusher, which directly contacts with the material and crushers it, so its material and fixing method directly affect the crushing efficiency. So what are the fixing methods of the impact crusher plate hammer? Here are the details.

The plate hammer of the impact crusher is generally made of wear-resistant high chromium cast iron material, and there are three main fixing methods: bolt fixing, plate fixing and wedge fixing, of which the latter two methods are more commonly used, which are described as follows:

Method 1: Bolt fixation

Bolt fixing is to fix the plate hammer on the plate hammer seat of the rotor by bolts. However, the screw is directly exposed to the striking surface, which is easily damaged, and the screw will be subjected to a large shear force, which will cause serious production accidents once it is cut. From the perspective of safety production, many large manufacturers do not use this fixed way.

Method 2: Clamp plate fixation

Clamping plate is that the plate hammer is inserted into the groove of the rotor from the side, in order to prevent axial movement, both ends are pressed by clamping plate. However, this method uses the welding process, the pressure plate is easy to wear and not easy to replace, and the plate hammer is not strong enough, and it is easy to loose and fall off in the crushing operation.

Method 3: Wedge fixation

Wedge fixing is to insert the wedge into the corresponding slot between the plate hammer and the rotor, and tighten it through extrusion. When the impact crusher is running, by the action of centrifugal force, the faster the rotor speed, the more firmly the plate hammer is fixed, and the more convenient to disassemble and replace. In addition, the rotor wear is reduced by avoiding the relative series shift between the plate hammer and the rotor. This is a better fixing method for the plate hammer at present, and most manufacturers generally use this fixing method.

Warm tips:

Bolt fastening method plate hammer utilization rate is higher, but the replacement is more troublesome, and not suitable for high impact load, generally large manufacturers have abandoned this method, small crusher manufacturers will still use; The method of clamping plate and wedge fixing, the metal utilization rate of the plate hammer is low, but the replacement is relatively convenient, and the operation is stable, and the production continuity is good, so these two fixing methods are more popular with users. If you want to know more about the impact crusher crusher, welcome to call or online consultation, message, Leitos machinery will send professionals to answer your questions.

+8615713843888

+8615713843888

+8615713843888

+8615713843888