The moving cone is an important part of the cone crusher, which is matched with the combination screws, spherical bearings, and the upper and lower bushings during the working process. Many users found in the process of use, due to the need to contact with hard materials, coupled with other factors often appear cone damage. The following is your analysis of the cone breaking mechanical cone damage factors:

1, improper compression of the spring

After the cone crusher is put into use, if there is severe vibration, low production efficiency, large mechanical particle size and other phenomena, it is the performance of the cone crusher compression force shortcomings, some manufacturers in order to produce smoothly, will adjust the compression amount of the spring again, although increasing the compression force of the cone crusher, but it increases the work burden of the cone, affecting the damage of the cone.

2, mechanical load operation

In line with the production policy of more breaking and less grinding, reducing cost and increasing efficiency, many manufacturers will improve the productivity of cone crusher by reducing the size of qualified ore and increasing the amount of ore, resulting in load operation, which will increase the burden of the moving cone in depth, and eventually lead to the damage of the starting cone.

- The moving cone is affected more

When the cone crusher has non-broken into the machinery, the entrance to the ore uneven or cone crusher lock cylinder damage will lead to the starting cone by the impact load is more often, when a transient impact load close to the mechanical performance limit of the moving cone, its weak parts will be damaged, there are small micro cracks, under the influence of heavy load, alternating load, micro cracks gradually expand, resulting in the moving cone damage.

4, the moving cone force is not balanced

When the cone crusher is working, the force it bears is mainly the inertia force of the cone, the self-gravity of the active cone, the counter-influence of the spherical bearing, the counter-influence of the eccentric bushing, the inertia force of the crushing cone and the eccentric bushing (including the balanced weight), etc. If the resultant force of these forces is not zero, the moving cone will be stressed unbalanced, causing excessive mechanical vibration, and the moving cone is damaged.

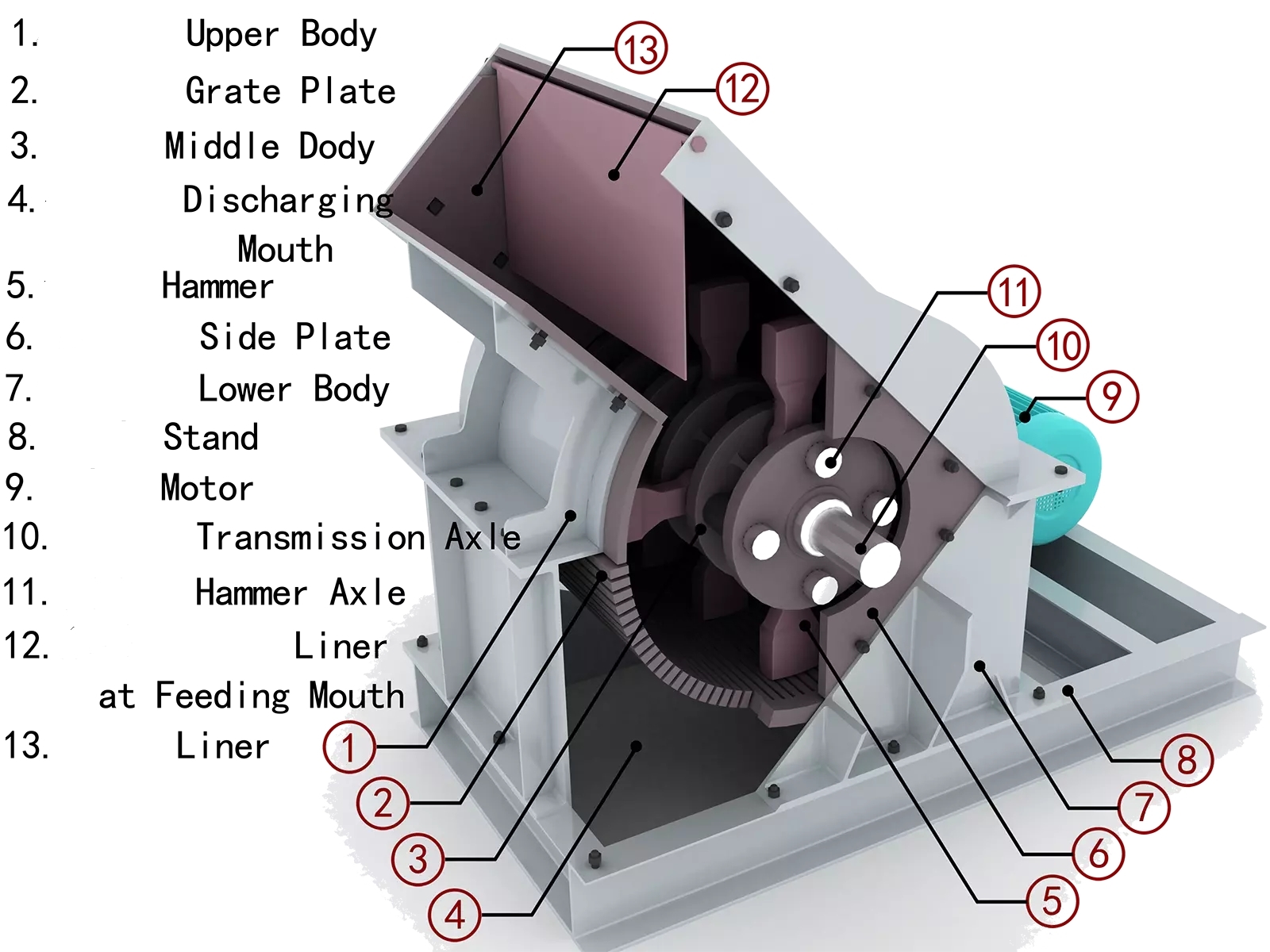

Cone crusher

- The moving cone is loose

Since there is no inspection tool for the preloading force between the moving cone head and the main shaft thread, maintenance workers can grasp it by experience in actual operation. After the gear meshing between the stop gear and the cone head, the preloading force can not meet the technical requirements. When the cone crusher is running under load, the cone head becomes loose, resulting in the wear of the gear and the moving cone. - Poor contact of the support surface

The moving cone of the cone crusher is supported on the spherical bearing block of the spherical bearing block. When the spherical bearing block is worn or there are performance problems, the moving cone will be affected to move down, and the supporting contact surface can not be in good contact, which causes the starting cone friction to accelerate and cause serious damage.

This paper mainly introduces what are the factors that cause the damage of the cone crusher, hoping to be helpful to everyone when using the cone crusher. If you want to know more about the crusher, welcome to call or online consultation, message, Leitos machinery will send professionals to answer your questions.

+8615713843888

+8615713843888

+8615713843888

+8615713843888