At present, the vast majority of existing artificial sand production lines adopt wet production technology. Regardless of the form of sand washing machine used, the biggest disadvantage is the serious loss of fine sand (particles below 0.16mm), and some even lose more than 20%. This not only causes serious losses, but also seriously affects the grading of sand, resulting in unreasonable grading and coarse fineness modulus, greatly reducing the quality of machine-made sand products. Excessive discharge of fine sand can also cause environmental pollution.

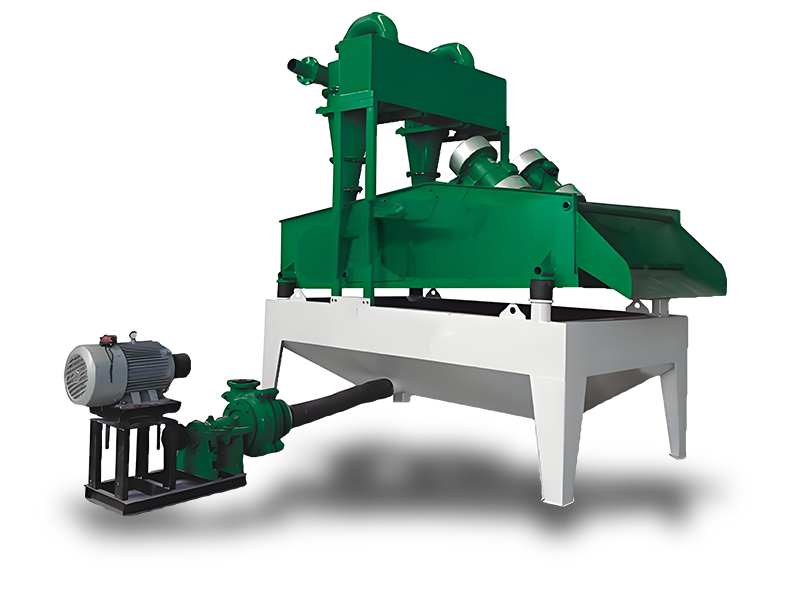

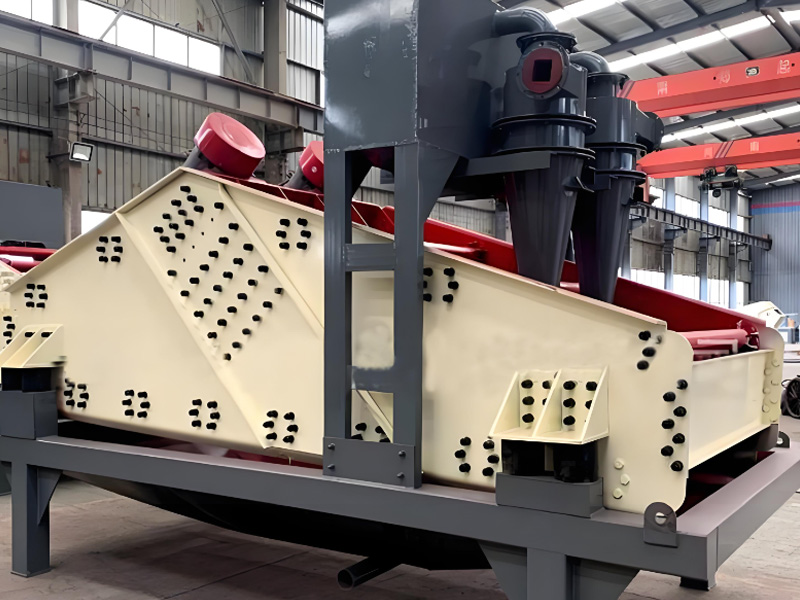

To solve the above problems, our company has successfully researched the XH series fine sand recovery device. This system is an advanced fine material extraction device designed by our company by absorbing advanced foreign technology and combining it with the actual situation of sand powder. It is widely used in the sand and gravel processing system of hydropower stations, glass raw material processing system, artificial sand production line, coarse coal slurry recovery in coal preparation plants, and environmental protection engineering (mud purification), which can effectively solve the problem of fine sand recovery.

| Model | Sand pump | High-pressure separator specification(mm) |

Dehydration screen | Water treatment (m³/h) |

|||

| Power(kw) | Material | Model | Material | Power(kw) | |||

| XH-250 | 11 | Cr26 | 250 | 6×2.25 | Polymer polyurethane | 2×0.75 | 30-60 |

| XH-300 | 15 | Cr26 | 300 | 8×2.25 | Polymer polyurethane | 2×0.75 | 60-100 |

| XH-350 | 18.5 | Cr26 | 350 | 10×2.25 | Polymer polyurethane | 2×1.1 | 70-130 |

| XH-500 | 22 | Cr26 | 500 | 12×3.0 | Polymer polyurethane | 2×1.1 | 100-220 |

| XH-600 | 30 | Cr26 | 600 | 12×3.0 | Polymer polyurethane | 2×1.5 | 120-272 |

| XH-700 | 37 | Cr26 | 700 | 14×3.0 | Polymer polyurethane | 2×1.5 | 180-350 |

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

+8615713843888

+8615713843888

+8615713843888

+8615713843888