Sand making machine, also known as vertical impact crusher. It is a common crushing equipment in the production process of sand and gravel aggregates, mainly used to crush medium crushed products into 3-5mm sand. By investigating some relevant data during the use of the sand making machine, it is possible to determine whether the equipment is operating properly, detect equipment failures in a timely manner, and handle them faster and better to prevent greater losses to users. Here, we will introduce the precautions for using the sand making machine.

Ampere meter reading – investigate its fluctuation situation

A high current may indicate a large amount of feed, excessive accumulation of material in the crushing chamber or machine base, friction between the feeding pipe and the impeller receiving port, blockage of the discharge hopper, or mechanical or electrical failure.

A low current may indicate insufficient feeding, slipping of the drive belt, or an electrical malfunction.

The different currents of the dual drive motors may indicate uneven adjustment of the drive belt tension, indicating electrical or mechanical faults. The current error between the two motors should be less than 20A.

Noise level

An increase in noise may indicate bearing damage, slipping of the drive belt, wear of accumulated material in the crushing chamber, and friction between the feeding pipe and impeller.

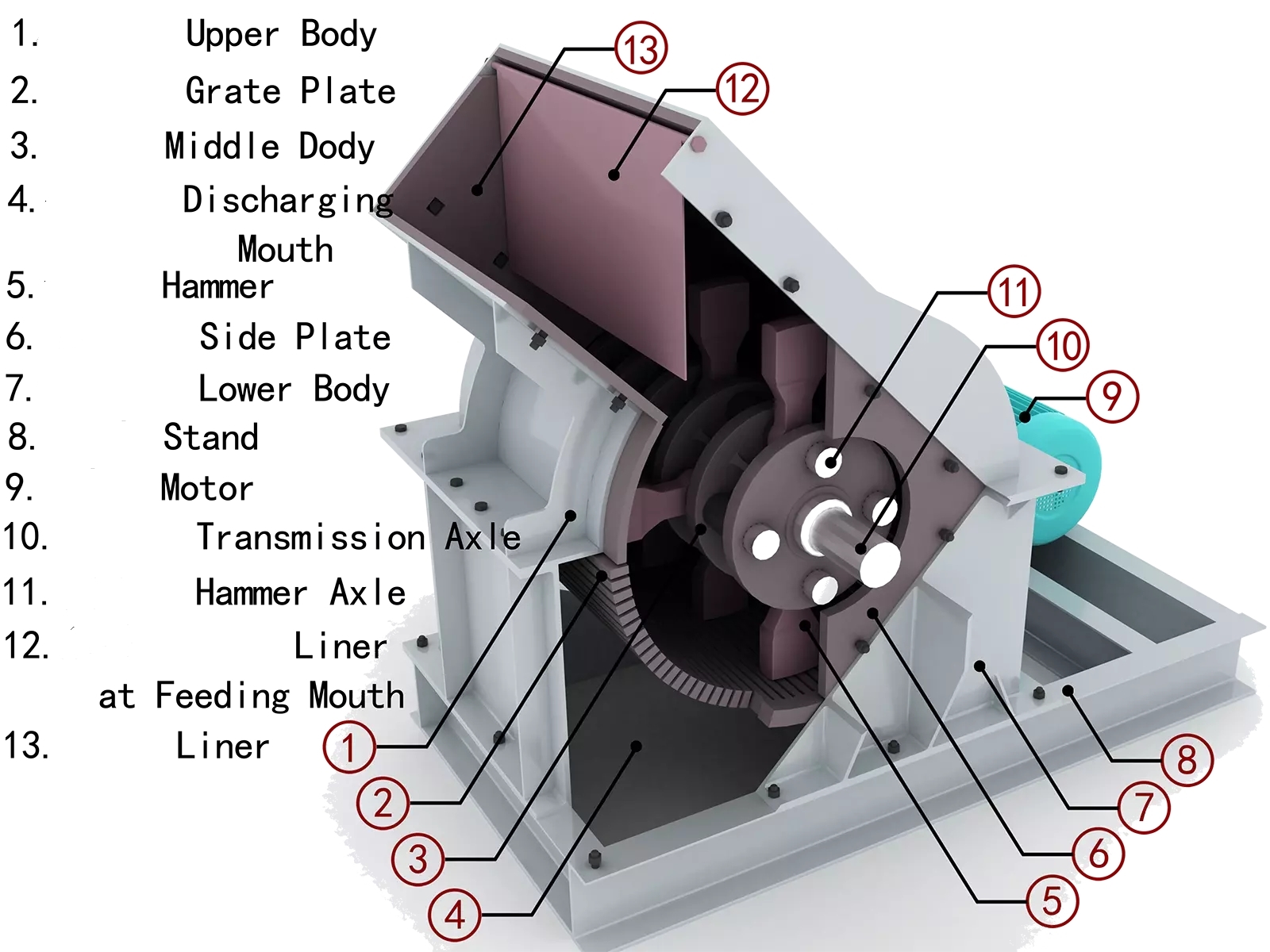

Precautions for Sand Making Machine – Structure

Vibration

Increased vibration may indicate uneven wear of worn parts or rotors, rotor imbalance caused by uneven material accumulation, damaged anti vibration pads, or loose rotor or pulley cone sleeves.

Material flow rate

The increase in feed humidity may increase the amount of accumulated material in the rotor, crushing chamber, and machine base. After investigating the discharge of the crusher, it is usually found that the condition of accumulated material is related.

Dust emissions

When feeding, there should not be a large amount of dust emissions. Otherwise, it should be checked that too little feeding may cause the crusher to emit dust from the feeding hopper and discharge hopper.

+8615713843888

+8615713843888

+8615713843888

+8615713843888