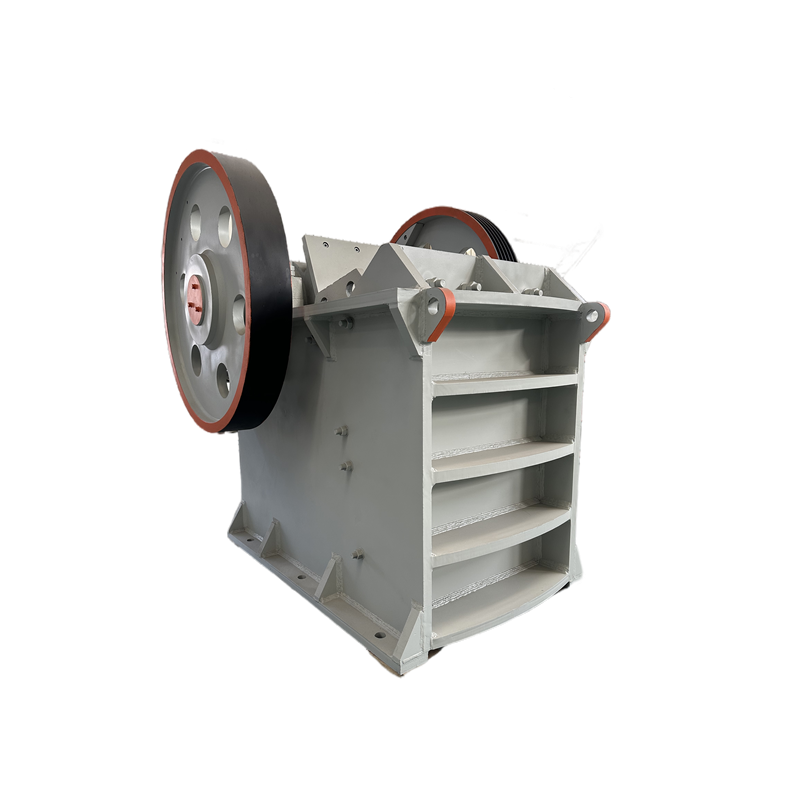

The jaw crusher is a common coarse crushing equipment in the sand and stone production line. Whether it is medium and high hardness stone or low hardness stone, it can be used to achieve the crushing effect of large crushing ratio and uniform particle size. With the operation of the equipment, the wear of the crushing gear plate increases, the discharge port gradually increases, and the particle size of the broken product continues to coarser. In order to ensure the requirements of the product particle size, the adjustment device must be used to adjust the size of the discharge port regularly. This article is mainly to share with you some of the jaw crusher discharge port adjustment knowledge, together to understand it!

First, what are the adjustment ways of discharge port?

Jaw crusher commonly used discharge port adjustment mode, there are mainly the following 4 kinds:

1, gasket adjustment

A set of spacers of equal thickness are placed between the rear thrust plate support and the rear wall of the frame. By increasing or decreasing the number of gasket layers, the discharge port of the crusher is reduced or enlarged. This method can achieve multi-stage adjustment, but must stop when adjusting. Large jaw crusher, use this adjustment method.

2, support device adjustment

The support device of the jaw crusher is mainly used to support the eccentric shaft and the suspension shaft, so that they are stable on the frame. The support device can use two kinds of sliding bearings and rolling bearings, with the improvement and optimization of the development of equipment, rolling bearings have gradually replaced the sliding bearings, which not only reduces the friction loss, but also brings the benefits of easy maintenance, good lubrication conditions and not easy to leak oil. The size of the discharge port can also be controlled by adjusting the support device.

- Wedge adjustment

With the help of the relative movement of two wedges between the rear thrust plate support and the rear wall of the frame, the crusher discharge port is adjusted. Turn the nut on the bolt to make the adjustment block move up or down along the back wall of the frame, and drive the front block to move forward or backward; Thus, the thrust plate and the moving jaw are driven to achieve the purpose of adjusting the discharge port. This method can achieve stepless adjustment, adjustment is convenient, save time, do not need to stop adjustment, but increase the size and weight of the machine. Medium and small jaw crusher often use this adjustment device.

4, hydraulic adjustment

The hydraulic device is installed in the position of the discharge port, and the function of the discharge port adjustment can also be realized. The hydraulic safety device is adopted in the jaw crusher, which is reliable and safe, and easy to troubleshoot. When the crushing chamber of the jaw crusher enters the debris, in order to avoid machine damage, the rear thrust plate is used as the protective device of the crusher.

- How often is the discharge port adjusted?

Under normal circumstances, the size of the discharge port needs to be adjusted once every one month or so. In the production, if the size of the discharge port is found to change greatly, it should also be adjusted in time.

In summary, the discharge port adjustment method of jaw crusher includes gasket adjustment, support device adjustment, wedge adjustment and hydraulic adjustment, etc. The specific choice of which method depends on the model, specifications and actual working needs of the crusher . If you want to know more about the jaw crusher, welcome to call or online consultation, message, Leitos machinery will send professionals to answer your questions.

+8615713843888

+8615713843888

+8615713843888

+8615713843888