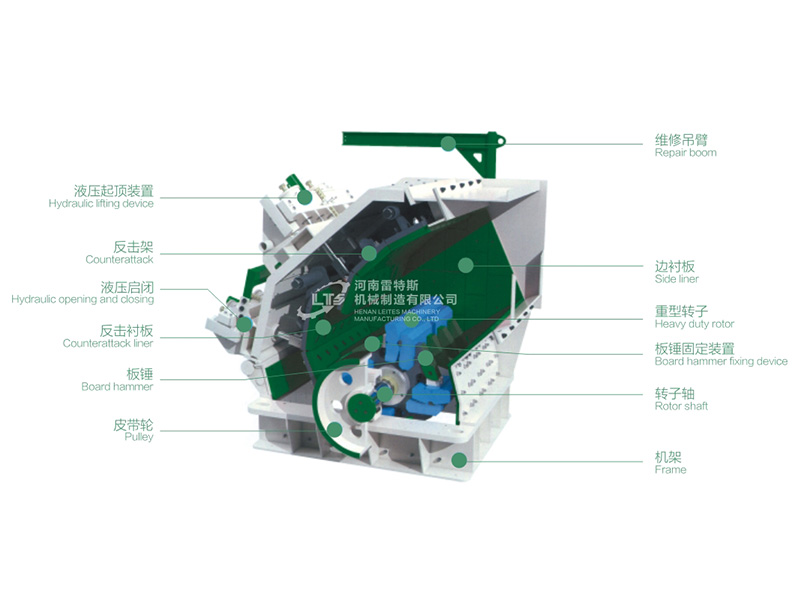

The European version of the impact crusher is a crushing machinery that uses impact energy to crush materials. This crushing equipment can process various materials with a particle size not exceeding 1000 millimeters and a compressive strength not exceeding 350 megapascals. It has the characteristics of high crushing ratio, high crushing efficiency, and easy maintenance. The product is in the form of a cube and is an ideal processing equipment for aggregates used in high-end highway surfaces and hydropower construction. The impact crusher is widely used in fields such as highway construction, water conservancy engineering, and crushed stone processing for construction due to its stable performance and excellent performance.

| Model | Feed opening size(mm) |

Max feed Size (mm) |

Capacity (t/h) |

Power (kw) |

| PFV150 | 820×980 | 100-600 | 100-200 | 90-200 |

| PFV250 | 960×1360 | 100-750 | 200-400 | 180-250 |

| PFV350 | 1050×1700 | 100-800 | 300-500 | 200-400 |

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

+8615713843888

+8615713843888

+8615713843888

+8615713843888