Crushing Equipment Market Size 2024-2028

The crushing equipment market size is forecast to increase by USD 435.9 million, at a CAGR of 3.72% between 2024 and 2028. Market expansion hinges on several critical factors: the increasing adoption of artificial sand in construction projects, global demand surges for housing developments, and the stability of crude oil prices. The utilization of artificial sand is revolutionizing construction practices by offering a sustainable alternative to natural sand, addressing environmental concerns and ensuring a reliable supply for infrastructure projects. Concurrently, the global housing sector’s robust growth drives the need for construction materials, including artificial sand, to meet escalating urbanization and population demands worldwide.

Additionally, stable crude oil prices are pivotal as they influence construction costs, transportation expenses, and overall economic stability, thereby impacting market dynamics significantly. These interconnected factors underscore the complex interplay between materials innovation, global housing trends, and economic conditions, shaping the trajectory of construction and related industries on a global scale. Understanding and navigating these dynamics is crucial for stakeholders aiming to capitalize on emerging opportunities in the market.

Crushing Equipment Market Size 2024-2028

The crushing equipment market size is forecast to increase by USD 435.9 million, at a CAGR of 3.72% between 2024 and 2028. Market expansion hinges on several critical factors: the increasing adoption of artificial sand in construction projects, global demand surges for housing developments, and the stability of crude oil prices. The utilization of artificial sand is revolutionizing construction practices by offering a sustainable alternative to natural sand, addressing environmental concerns and ensuring a reliable supply for infrastructure projects. Concurrently, the global housing sector’s robust growth drives the need for construction materials, including artificial sand, to meet escalating urbanization and population demands worldwide.

Additionally, stable crude oil prices are pivotal as they influence construction costs, transportation expenses, and overall economic stability, thereby impacting market dynamics significantly. These interconnected factors underscore the complex interplay between materials innovation, global housing trends, and economic conditions, shaping the trajectory of construction and related industries on a global scale. Understanding and navigating these dynamics is crucial for stakeholders aiming to capitalize on emerging opportunities in the market.

What will be the Size of the Market During the Forecast Period?

To learn more about this report, View Report Sample

Market Dynamic and Customer Landscape

The market plays a crucial role in housing activities and construction by supplying essential building materials like stone chips. As infrastructure spending drives demand, crushers support projects ranging from bridges and highways to city transit and railways, facilitating construction activities and canal development worldwide. World Mining Data influences mining production of materials processed by stone crushers, measured in metric tons. Innovations like mobile cone crushers and rental models cater to diverse operational needs, enhancing efficiency in economies reliant on robust building and mining sectors. This dynamic market integrates with Congress initiatives focusing on economic growth through sustainable infrastructure development, ensuring the availability of essential building materials to support global urbanization and economic expansion.

Key Market Driver

The use of artificial sand for construction work is notably driving the market growth. Construction and infrastructure projects make use of river sand. River sand provides strength, bulk, and adhesive properties to construction materials, such as cement, brick, asphalt, and concrete. It is also used for landscaping projects. However, since 2010, many regional governments and countries have banned the export of river sand. This is because sand mining results in the erosion of river banks and negatively impacts biodiversity. It is also exhausting rapidly because of extensive mining. In addition, most infrastructure and construction projects are situated away from river banks. The transportation of river sand from river banks to construction sites proves to be difficult and adds to the overall cost of the project. Hence, construction project owners opt for better alternatives to river sand. The artificial sand produced by this equipment is one of the best substitutes for river sand.

Further, artificial sand is produced by crushing basalt or granite rock through a 3-stage process. It is expected that shortly, most countries will ban the use of natural river sand, which, in turn, will positively impact the use of artificial sand. Government regulations, increasing prices, and less availability drive the demand for artificial sand by construction project owners. The number of construction projects is expected to increase, which will drive the demand for artificial sand during the forecast period. Such factors will drive the growth of the market during the forecast period.

Significant Market Trends

Automation of crushing equipment is a major trend in the market. The material that is required to be crushed into smaller pieces is lifted from its source and transported to the surge bin near the equipment. The material is then loaded into the feeder of the equipment. After this, an operator runs this equipment manually till the entire process is completed. Small parts of the material that are procured after the original material are then transported to a screener that separates them according to their sizes.

Moreover, operating this equipment manually consumes more time and requires a highly skilled workforce. This operation time can be minimized if this equipment is connected to another construction equipment and their operations are automated. The whole operation can be automated by installing sensors in the equipment. If the entire process is automated, the original material to be crushed can be loaded into the conveyor belt from the source. This conveyor belt can then load the material into the feeder, where sensors will detect it and automatically start the process of material crushing. Automation can reduce the operation and transportation time, minimize the number of operators required to run the entire process, and decrease the overall cost. Thus, the increasing demand for automation of this equipment will drive the growth of the global market during the forecast period.

Major Market Challenge

Environmental issues are a major challenge impeding the market. All quarrying and stone processing operations, such as surface mining, screening, crushing, and material handling, are sources of high particulate emissions. During the operations, the generation of a significant amount of particulate matter is inherent, and these emissions are most frequent at the crusher feed and discharge points. The greater the reduction ratio during subsequent stages from primary to tertiary crushing, the higher the emission levels.

Further, primary jaw crushers generate more particulate emissions and dust than cone crushers due to the bellows effect of the jaw and because cone crushers are mostly choke-fed. This minimizes open spaces from where particulate emissions and dust may be emitted. For subsequent reduction stages, roller or cone-type crushers generate more particulate matter and dust. This is a major challenge that is expected to impede mining activities, which, in turn, will hinder the growth of the global market during the forecast period.

Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth and forecasting strategies.

Crushing Equipment Market Size 2024-2028

The crushing equipment market size is forecast to increase by USD 435.9 million, at a CAGR of 3.72% between 2024 and 2028. Market expansion hinges on several critical factors: the increasing adoption of artificial sand in construction projects, global demand surges for housing developments, and the stability of crude oil prices. The utilization of artificial sand is revolutionizing construction practices by offering a sustainable alternative to natural sand, addressing environmental concerns and ensuring a reliable supply for infrastructure projects. Concurrently, the global housing sector’s robust growth drives the need for construction materials, including artificial sand, to meet escalating urbanization and population demands worldwide.

Additionally, stable crude oil prices are pivotal as they influence construction costs, transportation expenses, and overall economic stability, thereby impacting market dynamics significantly. These interconnected factors underscore the complex interplay between materials innovation, global housing trends, and economic conditions, shaping the trajectory of construction and related industries on a global scale. Understanding and navigating these dynamics is crucial for stakeholders aiming to capitalize on emerging opportunities in the market.

What will be the Size of the Market During the Forecast Period?

To learn more about this report, View Report Sample

Market Dynamic and Customer Landscape

The market plays a crucial role in housing activities and construction by supplying essential building materials like stone chips. As infrastructure spending drives demand, crushers support projects ranging from bridges and highways to city transit and railways, facilitating construction activities and canal development worldwide. World Mining Data influences mining production of materials processed by stone crushers, measured in metric tons. Innovations like mobile cone crushers and rental models cater to diverse operational needs, enhancing efficiency in economies reliant on robust building and mining sectors. This dynamic market integrates with Congress initiatives focusing on economic growth through sustainable infrastructure development, ensuring the availability of essential building materials to support global urbanization and economic expansion.

Key Market Driver

The use of artificial sand for construction work is notably driving the market growth. Construction and infrastructure projects make use of river sand. River sand provides strength, bulk, and adhesive properties to construction materials, such as cement, brick, asphalt, and concrete. It is also used for landscaping projects. However, since 2010, many regional governments and countries have banned the export of river sand. This is because sand mining results in the erosion of river banks and negatively impacts biodiversity. It is also exhausting rapidly because of extensive mining. In addition, most infrastructure and construction projects are situated away from river banks. The transportation of river sand from river banks to construction sites proves to be difficult and adds to the overall cost of the project. Hence, construction project owners opt for better alternatives to river sand. The artificial sand produced by this equipment is one of the best substitutes for river sand.

Further, artificial sand is produced by crushing basalt or granite rock through a 3-stage process. It is expected that shortly, most countries will ban the use of natural river sand, which, in turn, will positively impact the use of artificial sand. Government regulations, increasing prices, and less availability drive the demand for artificial sand by construction project owners. The number of construction projects is expected to increase, which will drive the demand for artificial sand during the forecast period. Such factors will drive the growth of the market during the forecast period.

Significant Market Trends

Automation of crushing equipment is a major trend in the market. The material that is required to be crushed into smaller pieces is lifted from its source and transported to the surge bin near the equipment. The material is then loaded into the feeder of the equipment. After this, an operator runs this equipment manually till the entire process is completed. Small parts of the material that are procured after the original material are then transported to a screener that separates them according to their sizes.

Moreover, operating this equipment manually consumes more time and requires a highly skilled workforce. This operation time can be minimized if this equipment is connected to another construction equipment and their operations are automated. The whole operation can be automated by installing sensors in the equipment. If the entire process is automated, the original material to be crushed can be loaded into the conveyor belt from the source. This conveyor belt can then load the material into the feeder, where sensors will detect it and automatically start the process of material crushing. Automation can reduce the operation and transportation time, minimize the number of operators required to run the entire process, and decrease the overall cost. Thus, the increasing demand for automation of this equipment will drive the growth of the global market during the forecast period.

Major Market Challenge

Environmental issues are a major challenge impeding the market. All quarrying and stone processing operations, such as surface mining, screening, crushing, and material handling, are sources of high particulate emissions. During the operations, the generation of a significant amount of particulate matter is inherent, and these emissions are most frequent at the crusher feed and discharge points. The greater the reduction ratio during subsequent stages from primary to tertiary crushing, the higher the emission levels.

Further, primary jaw crushers generate more particulate emissions and dust than cone crushers due to the bellows effect of the jaw and because cone crushers are mostly choke-fed. This minimizes open spaces from where particulate emissions and dust may be emitted. For subsequent reduction stages, roller or cone-type crushers generate more particulate matter and dust. This is a major challenge that is expected to impede mining activities, which, in turn, will hinder the growth of the global market during the forecast period.

Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth and forecasting strategies.

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Astec Industries Inc. – The company offers Asphalt plants and related components, Asphalt pavers, Asphalt storage tanks, Milling machines, and others.

The research report also includes detailed analyses of the competitive landscape of the market and information about 20 market companies, including:

- Caterpillar Inc.

- Deere and Co.

- Eagle Crusher Co. Inc.

- FLSmidth and Co. AS

- IROCK Crushers

- Komatsu Ltd.

- McLanahan Corp.

- Metso Outotec Corp.

- Minyu Machinery Corp.

- Mormak Equipment Inc.

- R.R. EQUIPMENT Co.

- Rock Engineered Machinery Co. Inc.

- Sandvik AB

- SCREEN MACHINE INDUSTRIES LLC

- Shibang Industry and Technology Group Co. Ltd.

- Terex Corp.

- The Weir Group Plc

- thyssenkrupp AG

- Zhengzhou YiFan Machinery Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Market Segmentation

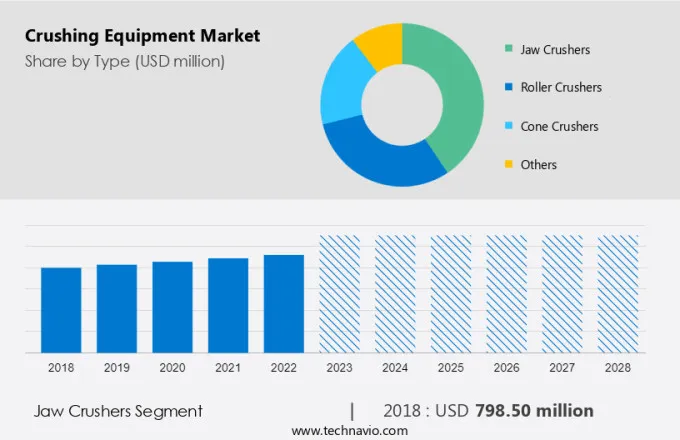

The market share growth by the jaw crushers segment will be significant during the forecast period. Jaw crushers can crush materials that are soft or very hard without any abrasion limits. Jaw crushers are also called universal crushers, as they can be used in various sectors, such as quarrying, heavy mining, and recycling. They are used in both infrastructure and mining projects, owing to their diverse use.

The jaw crushers segment was valued at USD 798.50 million in 2018. The major factor for this growth rate is innovation and technological advances in this segment, such as the increased crushing rate of materials. Companies come up with the latest models from time to time, which can crush more materials per hour. This increases productivity and provides a uniform product. companies also try to provide enhanced protection to crushers by offering advanced relief systems. These systems protect jaw crushers in the event of an entry of any uncrushable object into the crusher. This, as a result, attracts many potential customers from different industries. In addition, factors such as long shelf life, high productivity, easy maintenance, cost-effectiveness, flexibility, convenient replacement of spare parts, the range of feeding capacity, the reduction ratio of materials, low noise pollution, and low energy consumption will increase global demand.

Crushing Equipment Market Size 2024-2028

The crushing equipment market size is forecast to increase by USD 435.9 million, at a CAGR of 3.72% between 2024 and 2028. Market expansion hinges on several critical factors: the increasing adoption of artificial sand in construction projects, global demand surges for housing developments, and the stability of crude oil prices. The utilization of artificial sand is revolutionizing construction practices by offering a sustainable alternative to natural sand, addressing environmental concerns and ensuring a reliable supply for infrastructure projects. Concurrently, the global housing sector’s robust growth drives the need for construction materials, including artificial sand, to meet escalating urbanization and population demands worldwide.

Additionally, stable crude oil prices are pivotal as they influence construction costs, transportation expenses, and overall economic stability, thereby impacting market dynamics significantly. These interconnected factors underscore the complex interplay between materials innovation, global housing trends, and economic conditions, shaping the trajectory of construction and related industries on a global scale. Understanding and navigating these dynamics is crucial for stakeholders aiming to capitalize on emerging opportunities in the market.

What will be the Size of the Market During the Forecast Period?

To learn more about this report, View Report Sample

Market Dynamic and Customer Landscape

The market plays a crucial role in housing activities and construction by supplying essential building materials like stone chips. As infrastructure spending drives demand, crushers support projects ranging from bridges and highways to city transit and railways, facilitating construction activities and canal development worldwide. World Mining Data influences mining production of materials processed by stone crushers, measured in metric tons. Innovations like mobile cone crushers and rental models cater to diverse operational needs, enhancing efficiency in economies reliant on robust building and mining sectors. This dynamic market integrates with Congress initiatives focusing on economic growth through sustainable infrastructure development, ensuring the availability of essential building materials to support global urbanization and economic expansion.

Key Market Driver

The use of artificial sand for construction work is notably driving the market growth. Construction and infrastructure projects make use of river sand. River sand provides strength, bulk, and adhesive properties to construction materials, such as cement, brick, asphalt, and concrete. It is also used for landscaping projects. However, since 2010, many regional governments and countries have banned the export of river sand. This is because sand mining results in the erosion of river banks and negatively impacts biodiversity. It is also exhausting rapidly because of extensive mining. In addition, most infrastructure and construction projects are situated away from river banks. The transportation of river sand from river banks to construction sites proves to be difficult and adds to the overall cost of the project. Hence, construction project owners opt for better alternatives to river sand. The artificial sand produced by this equipment is one of the best substitutes for river sand.

Further, artificial sand is produced by crushing basalt or granite rock through a 3-stage process. It is expected that shortly, most countries will ban the use of natural river sand, which, in turn, will positively impact the use of artificial sand. Government regulations, increasing prices, and less availability drive the demand for artificial sand by construction project owners. The number of construction projects is expected to increase, which will drive the demand for artificial sand during the forecast period. Such factors will drive the growth of the market during the forecast period.

Significant Market Trends

Automation of crushing equipment is a major trend in the market. The material that is required to be crushed into smaller pieces is lifted from its source and transported to the surge bin near the equipment. The material is then loaded into the feeder of the equipment. After this, an operator runs this equipment manually till the entire process is completed. Small parts of the material that are procured after the original material are then transported to a screener that separates them according to their sizes.

Moreover, operating this equipment manually consumes more time and requires a highly skilled workforce. This operation time can be minimized if this equipment is connected to another construction equipment and their operations are automated. The whole operation can be automated by installing sensors in the equipment. If the entire process is automated, the original material to be crushed can be loaded into the conveyor belt from the source. This conveyor belt can then load the material into the feeder, where sensors will detect it and automatically start the process of material crushing. Automation can reduce the operation and transportation time, minimize the number of operators required to run the entire process, and decrease the overall cost. Thus, the increasing demand for automation of this equipment will drive the growth of the global market during the forecast period.

Major Market Challenge

Environmental issues are a major challenge impeding the market. All quarrying and stone processing operations, such as surface mining, screening, crushing, and material handling, are sources of high particulate emissions. During the operations, the generation of a significant amount of particulate matter is inherent, and these emissions are most frequent at the crusher feed and discharge points. The greater the reduction ratio during subsequent stages from primary to tertiary crushing, the higher the emission levels.

Further, primary jaw crushers generate more particulate emissions and dust than cone crushers due to the bellows effect of the jaw and because cone crushers are mostly choke-fed. This minimizes open spaces from where particulate emissions and dust may be emitted. For subsequent reduction stages, roller or cone-type crushers generate more particulate matter and dust. This is a major challenge that is expected to impede mining activities, which, in turn, will hinder the growth of the global market during the forecast period.

Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth and forecasting strategies.

Market Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Astec Industries Inc. – The company offers Asphalt plants and related components, Asphalt pavers, Asphalt storage tanks, Milling machines, and others.

The research report also includes detailed analyses of the competitive landscape of the market and information about 20 market companies, including:

- Caterpillar Inc.

- Deere and Co.

- Eagle Crusher Co. Inc.

- FLSmidth and Co. AS

- IROCK Crushers

- Komatsu Ltd.

- McLanahan Corp.

- Metso Outotec Corp.

- Minyu Machinery Corp.

- Mormak Equipment Inc.

- R.R. EQUIPMENT Co.

- Rock Engineered Machinery Co. Inc.

- Sandvik AB

- SCREEN MACHINE INDUSTRIES LLC

- Shibang Industry and Technology Group Co. Ltd.

- Terex Corp.

- The Weir Group Plc

- thyssenkrupp AG

- Zhengzhou YiFan Machinery Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Market Segmentation

The market share growth by the jaw crushers segment will be significant during the forecast period. Jaw crushers can crush materials that are soft or very hard without any abrasion limits. Jaw crushers are also called universal crushers, as they can be used in various sectors, such as quarrying, heavy mining, and recycling. They are used in both infrastructure and mining projects, owing to their diverse use.

Get a glance at the market contribution of various segments View the PDF Sample

The jaw crushers segment was valued at USD 798.50 million in 2018. The major factor for this growth rate is innovation and technological advances in this segment, such as the increased crushing rate of materials. Companies come up with the latest models from time to time, which can crush more materials per hour. This increases productivity and provides a uniform product. companies also try to provide enhanced protection to crushers by offering advanced relief systems. These systems protect jaw crushers in the event of an entry of any uncrushable object into the crusher. This, as a result, attracts many potential customers from different industries. In addition, factors such as long shelf life, high productivity, easy maintenance, cost-effectiveness, flexibility, convenient replacement of spare parts, the range of feeding capacity, the reduction ratio of materials, low noise pollution, and low energy consumption will increase global demand.

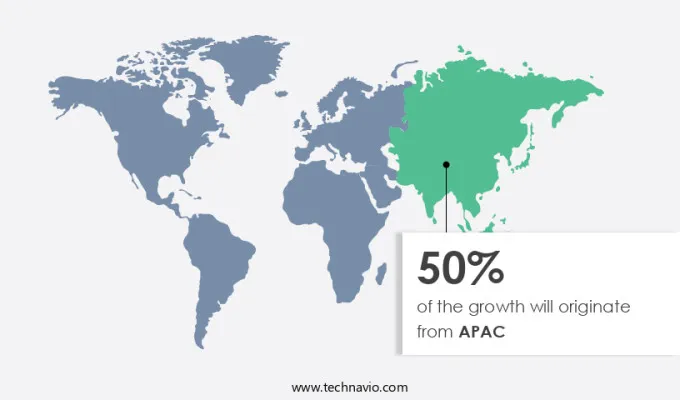

Regional Analysis

For more insights on the market share of various regions Download PDF Sample now!

APAC is estimated to contribute 50% to the growth of the global market during the forecast period. Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period. Construction equipment had better demand in APAC as compared with MEA, South America, and North America in 2022. This can be attributed to various infrastructure projects in APAC, which kept the demand for construction equipment strong, thus creating a healthy market environment as these projects use a significant amount of sand and gravel. Most high-scale infrastructure projects took place in China and India between 2011 and 2019. Governments of South-East Asian countries, such as Indonesia and the Philippines, have announced the development of many infrastructure projects, such as the construction of roads, airports, and railway lines, from 2015 to 2025. This is expected to result in an increased demand.

Segment Overview

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in “USD million” for the period 2024-2028, as well as historical data from 2018 – 2022 for the following segments.

- Type Outlook

- Jaw crushers

- Roller crushers

- Cone crushers

- Others

- End-user Outlook

- Mining

- Quarrying

- Recycling

- Construction and infrastructure

- Others

- Region Outlook

- North America

- The U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

- South America

- Chile

- Brazil

- Argentina

- North America

You may also interested in below market reports:

- Cone Crusher Market Cone Crusher Market Analysis APAC, North America, Europe, South America, Middle East and Africa – US, China, Japan, Germany, UK – Size and Forecast

- Construction and Mining Equipment Market Construction and Mining Equipment Market Analysis APAC, North America, Europe, Middle East and Africa, South America – US, Canada, China, India, Germany – Size and Forecast

- Mineral Processing Equipment Market Mineral Processing Equipment Market Analysis North America, APAC, Europe, South America, Middle East and Africa – US, China, Australia, India, Russia – Size and Forecast

Market Analyst Overview

The market is pivotal in various sectors, from copper mining to iron ore mining and road infrastructure development. Equipment such as jaw crushers and stone crushing machines are essential for processing materials like stone pellets and ensuring efficient mineral crushing operations. This supports the construction of buildings, canals, and high-rise structures, crucial for both long-term projects in the real estate sector and short-term projects in road development. Companies like IROCK Crusher and BUCY International leverage competitive advantages through innovative technical features, meeting the demands of passenger rail networks and public sectors alike. With a focus on durability and performance, crushing equipment plays a vital role in sustaining global metal surfaces production and enhancing budget efficiencies across diverse infrastructural and mining projects.

+8615713843888

+8615713843888

+8615713843888

+8615713843888