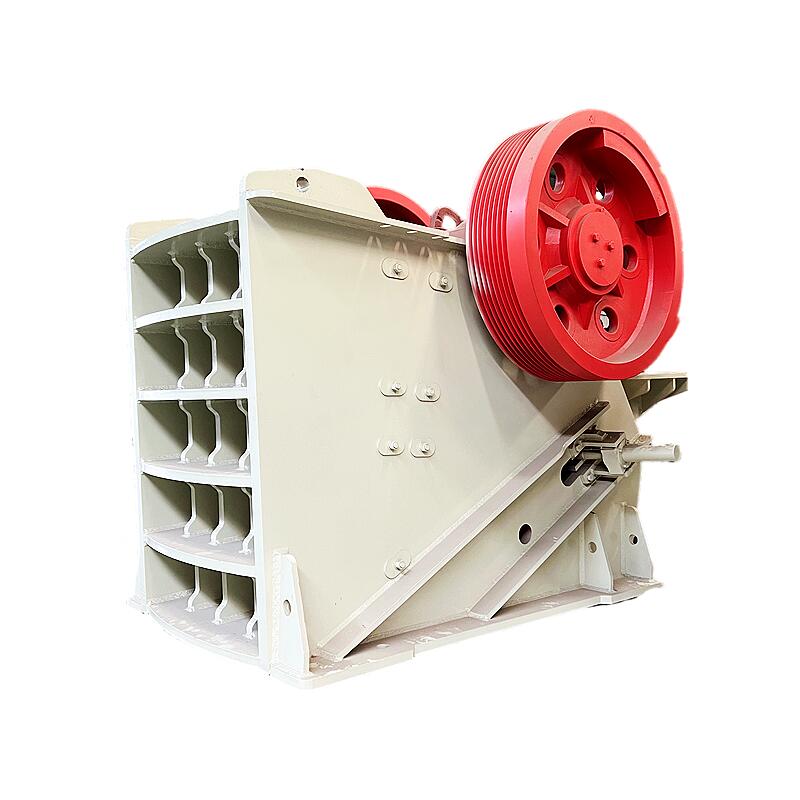

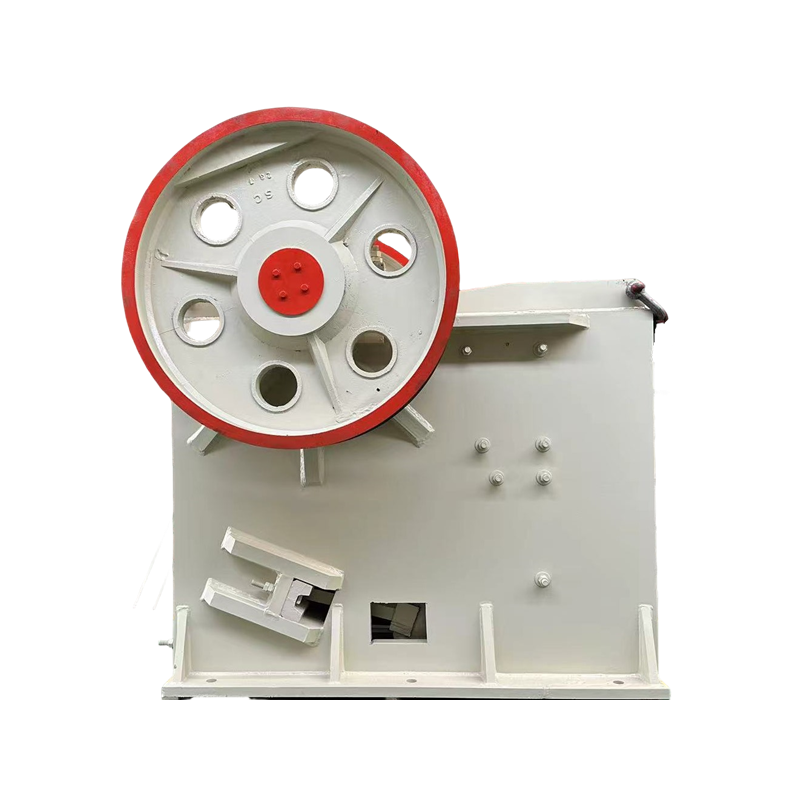

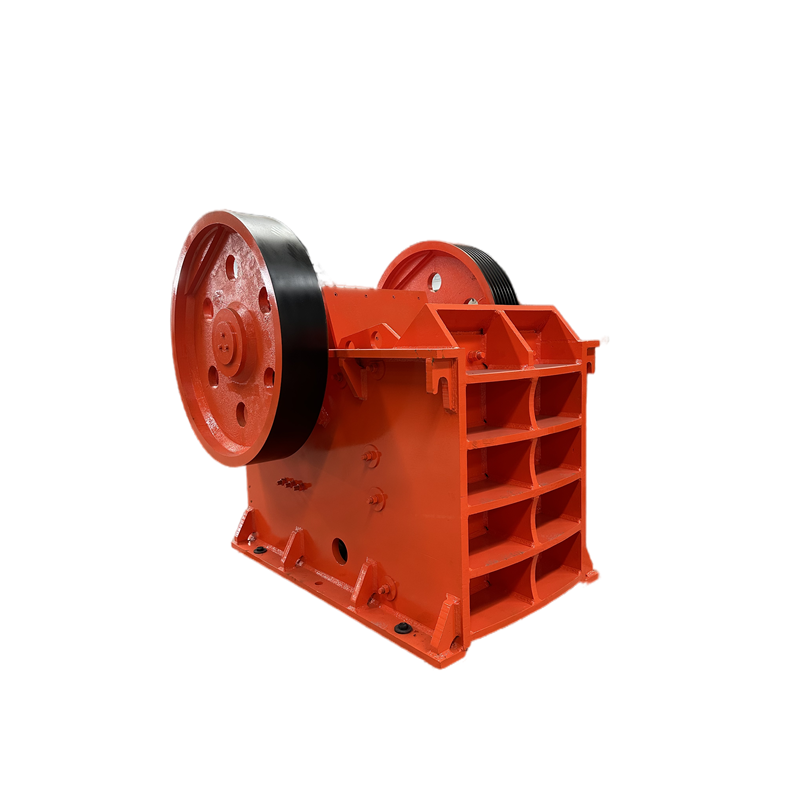

The jaw crusher is a commonly used coarse crushing equipment in mines, sand and gravel factories, etc. It has the features of large inertia force and heavy load operation. The working conditions of the jaw crusher directly affect the operation. Therefore, correct operation, reasonable and regular maintenance, accurate and timely judgment, elimination of possible faults in work, and proper handling of them are essential. Discover and solve problems quickly, restore production as soon as possible, and effectively ensure production efficiency. This article shares common faults and solutions during the operation of jaw crushers, and the debugging requirements after repairment.

Common Faults of Jaw Crusher with Solutions

- The adjustment mechanism is damaged, which affects material transportation.

Analyze the reasons:

- The wedge-shaped top base moves too much forward horizontally.

- The elbow and elbow pads are both self-purchased or modified, which is inconsistent with the design provided by the host manufacturer.

- Remove the fixing screws on the adjustment seat.

- The adjustment seat has serious casting or welding defects.

Solution: Pull the wedge top base backward. Replace the original crankshaft and gasket provided by the adjustment seat assembly host. Replace or tighten the adjustment base screws. Replace and adjust the base.

- Movable plate’s Fault

Analyze the reasons:

- Carrying too much payload.

- Defects left during casting, such as densely packed pores.

- Use low-quality elbows and elbow pads.

- When the tension spring fails, not replace it promptly.

- The amount of materials emitted is less than the required amount.

- The feeding position is incorrect, tilting towards one end, or the angle of the feeding hopper is too large, causing the material to impact the moving jaw head directly.

Solution:

In case of overload, reset the movable mouth and replace the original elbow pad. Correctly install the eccentric shaft, bearings, fixing sleeve, and movable gripper. Reinstall the tension spring and adjust the discharge according to the requirements. Add a feeding hopper to ensure uniform and smooth feeding, and separate from the middle to both sides.

- When the crusher is idling, there is a metallic impact sound at the bottom

There may be three possible reasons:

- The small mining mouth causes the collision between the movable jaw and the fixed jaw plate. It needs adjustment promptly.

- The impact sound inside the thrust plate bracket or gasket adjustment device is usually caused by the damage of the spring. The spring not being tightly compressed, resulting in rotation.

- When the jaw plate and elbow plate are not tightly combined with the main machine, the head of the elbow plate collides with the two end brackets, or the adjusting gasket collides, tighten the compression nut in time until the impact sound disappears.

It is also possible that the elbow joint support slider is severely waer or loose. When the elbow joint head is broken, it requires replacement immediately.

- Metal collision sound and lining plate shaking during work

The reason for this phenomenon is the loose lining and toothed plates on the side of the crushing chamber, or loose or broken fastening screws. It needs replacement promptly.

- Frequent fracture of the back elbow plate

- Because the rear elbow plate of the jaw crusher has a transmission function with low strength, which also plays a safety role. low strength in the middle of the elbow plate of the jaw crusher means its strength cannot offset the crushing force.

- The reason may be that the tension spring pressure of the rear elbow plate is too high, and excessive squeezing force may cause an overload of the rear elbow plate, leading to its fracture. It is necessary to adjust the pressure strength of the spring according to the production situation.

6. The flywheel rotates, causing the crusher to malfunction

- It is because of the pull rod and pull rod spring inside the jaw crusher are damaged. Meanwhile, if the elbow plate has already detached from the supporting slider, it can also cause the lining plate to break or even fall off, causing the crusher to malfunction.

- According to different issues, such as timely replacement of broken elbow plates, damage to pull rods or pull rod springs, and timely replacement of elbow plates due to slipping of pull rod nuts. After replacement, take an inspection and test before production.

7. The flywheel swings significantly, or the eccentric shaft turns back slowly.

The reason is damage or looseness of the pulley or flywheel key. As a result, the rotation of the wheel and shaft is not synchronized. If we detect this problem, it is necessary to tighten or replace the relevant parts.

8. Inconsistent product granularity with production requirements (coarsening)

It is because of severe wear of the broken lining plate. It is necessary to adjust the gear plate, or replace the lining plate and adjust the size of the ore discharge port to meet the requirements.

9. The bearing temperature exceeds the allowable temperature, and the return oil temperature exceeds 60℃.

The reason may be that the bearing shells are too tight. Adjust the degree of compression of the bearing shells by shims. Or the lubricating oil is insufficient, the lubricating oil circuit is block, and the lubricating oil is dirty. At this point, it is necessary to add lubricating oil, clean the oil pipe, and replace the lubricating oil.

10. The oil flow indicator shows a fuel cut-off

There may be a problem with the oil pump. Repair or replace the oil pump. In winter, if the oil temperature is too low, you can heat the oil.

Trial operation requirements for jaw crushers after major repairs

After the repair, the no-load trial run time is generally 2-6 hours. Empty driving should meet the following requirements:

- Start and stop according to the startup program, and the relevant interlocking system of the electrical part should meet maintenance requirements.

- All firmware should be firm and free from looseness.

- The lubrication at each point is normal and there is no oil leakage.

- The temperature rise of the bearing shall not exceed 30.

- The flywheel rotates smoothly.

- All adjustment mechanisms are flexible.

Improving the installation, use, and maintenance level of jaw crushers can prolong the service life of the equipment, improve the operating rate of the equipment, reducing energy consumption. It has great significance in the technical improvement and economic indicators of production, increasing the economic and social benefits of enterprises.

+8615713843888

+8615713843888

+8615713843888

+8615713843888