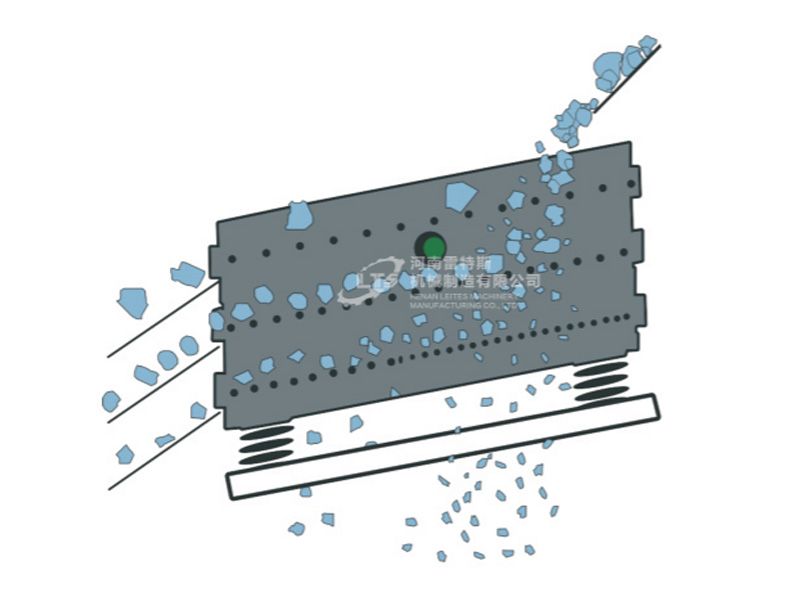

The circular vibrating screen performs circular motion and is a new type of multi-layer, high-efficiency vibrating screen. This machine adopts a simplified eccentric shaft exciter and an eccentric block to adjust the amplitude. The material screening line is long, and there are multiple screening specifications. It has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, easy maintenance, and safe use. It is widely used in product grading in industries such as mining, building materials, trading, energy and chemical industry.

| Model |

Screen mesh (mm) |

Layers |

Sieve pore size (mm) |

Max feed size (mm) |

Production capacity (t/h) |

Power(kw) |

Vibrating frequency (r/min) |

Double amplitude (mm) |

| 2YK1237 | 3700×1200 | 2 | 3-50 | 200 | 10-120 | 11 | 870 | 5-9 |

| 3YK1237 | 3700×1200 | 3 | 3-50 | 200 | 10-120 | 11 | 870 | 5-9 |

| 2YK1548 | 4800×1500 | 2 | 3-100 | 400 | 30-275 | 15 | 870 | 5-9 |

| 3YK1548 | 4800×1500 | 3 | 3-100 | 400 | 30-275 | 15 | 870 | 5-9 |

| 2YK1848 | 4800×1800 | 2 | 3-100 | 400 | 56-330 | 18.5 | 870 | 5-9 |

| 3YK1848 | 4800×1800 | 3 | 3-100 | 400 | 56-330 | 18.5 | 870 | 5-9 |

| 2YK1860 | 6000×1800 | 2 | 3-100 | 400 | 65-586 | 22 | 870 | 5-9 |

| 3YK1860 | 6000×1800 | 3 | 3-100 | 400 | 65-586 | 22-30 | 870 | 5-9 |

| 2YK2160 | 6000×2100 | 2 | 3-100 | 400 | 81-720 | 30 | 730 | 5-9 |

| 3YK2160 | 6000×2100 | 3 | 3-100 | 400 | 81-720 | 30-37 | 730 | 5-9 |

| 2YK2460 | 6000×2400 | 2 | 3-150 | 400 | 100-810 | 37 | 770 | 5-9 |

| 3YK2460 | 6000×2400 | 3 | 3-150 | 400 | 100-810 | 37 | 770 | 5-9 |

| 2YK2660 | 6000×2600 | 2 | 3-150 | 400 | 200-810 | 45 | 770 | 5-9 |

| 3YK2660 | 6000×2600 | 3 | 3-150 | 400 | 200-810 | 45 | 770 | 5-9 |

| 2YK3070 | 7000×3000 | 2 | 3-150 | 400 | 300-810 | 55 | 750 | 5-9 |

| 3YK3070 | 7000×3000 | 3 | 3-150 | 400 | 300-810 | 55 | 750 | 5-9 |

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

+8615713843888

+8615713843888

+8615713843888

+8615713843888