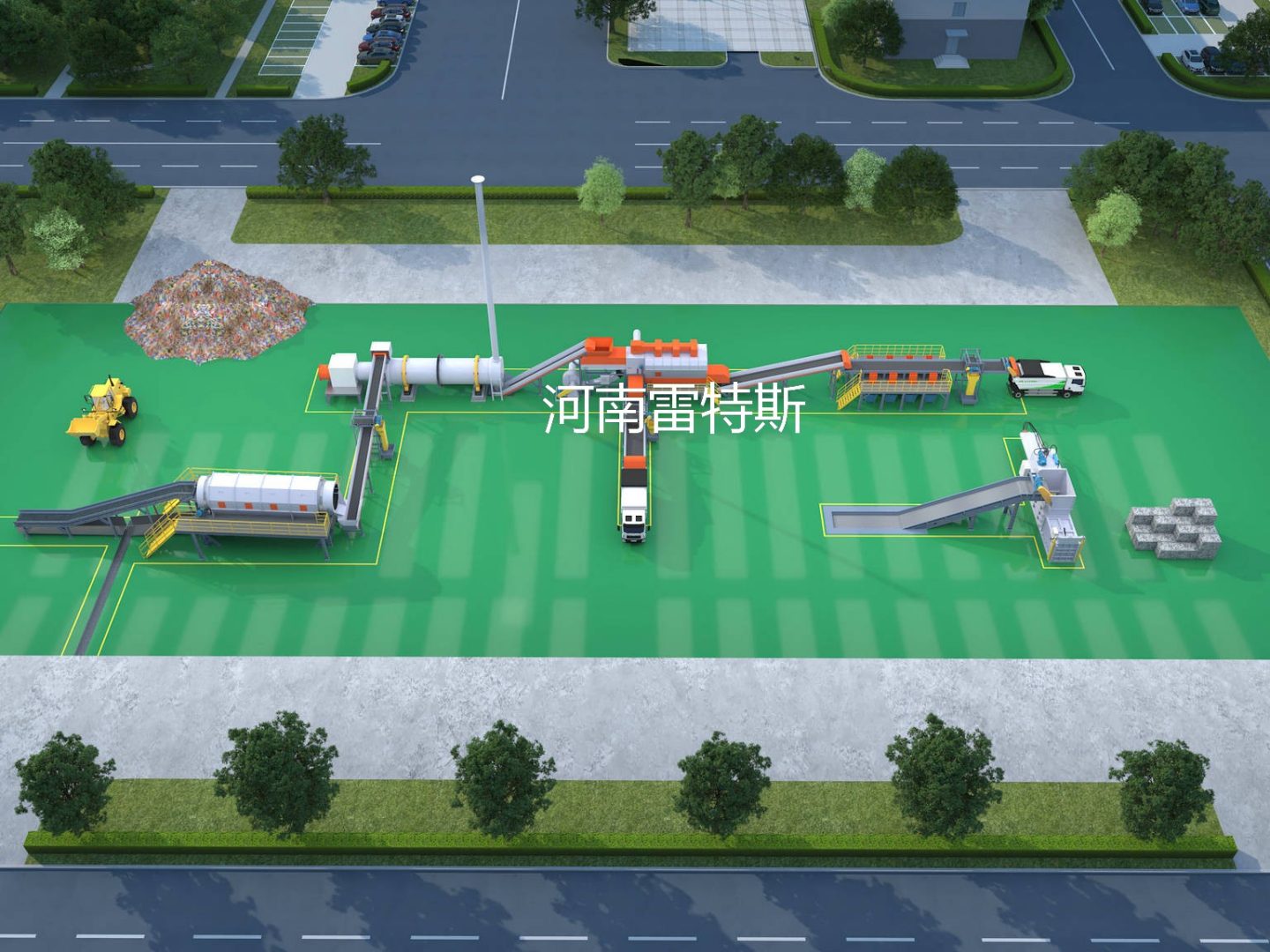

Construction waste sorting is a key link in realizing the resource utilization of construction waste. By sorting and screening construction waste, the recyclables, harmful substances and inert materials can be effectively separated, thereby improving resource utilization efficiency and reducing environmental burden. The following analyzes its advantages from multiple dimensions:

一. Resource recycling level

*Concrete and masonry: The sorted concrete blocks, masonry, etc. can be crushed and processed into recycled aggregates, used for road bases, landfill cushions or low-grade concrete production, replacing natural sand and gravel, and alleviating the problem of aggregate shortage.

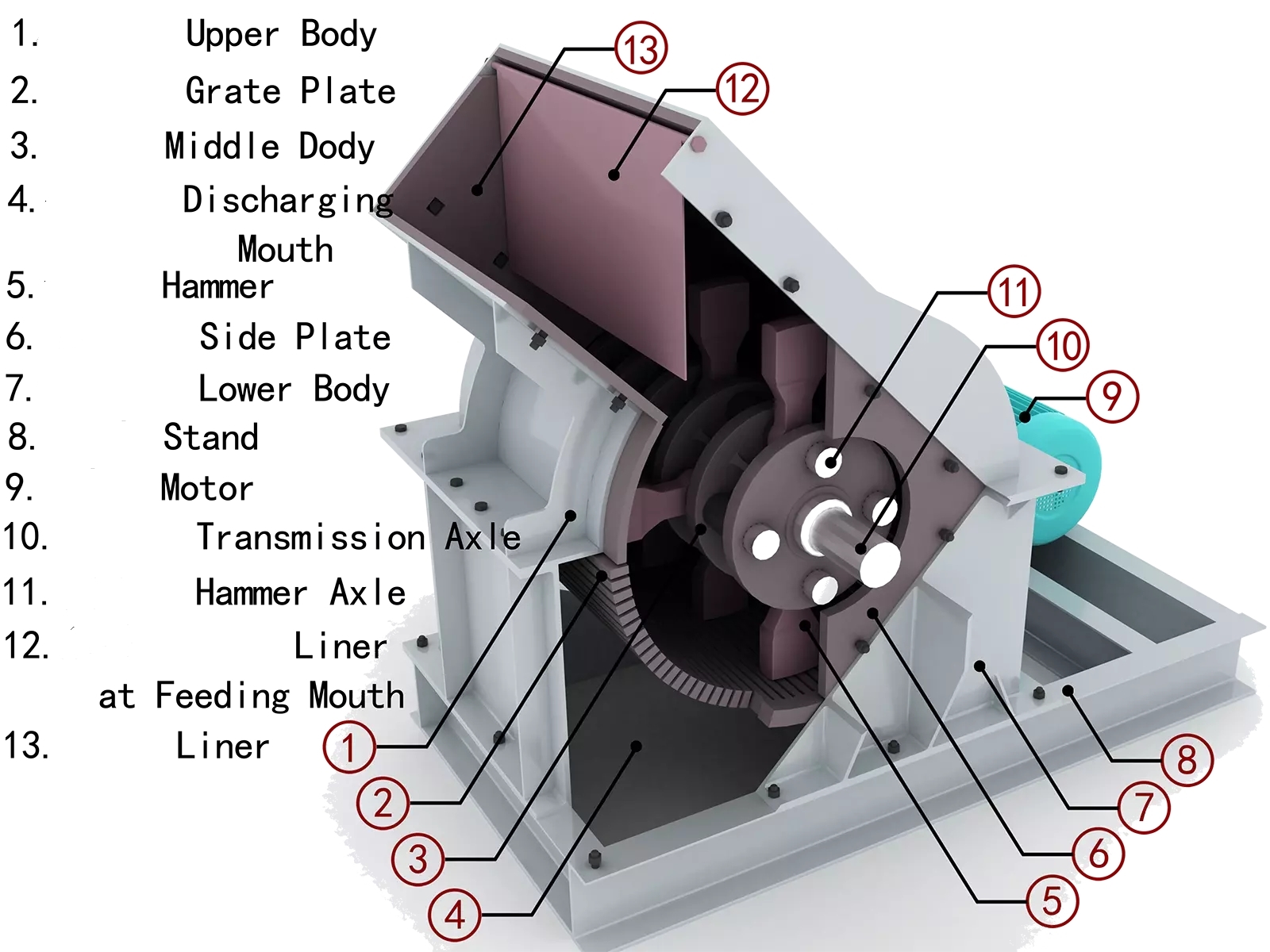

*Metal materials: After steel bars, iron wire and other metals are separated by magnetic separation equipment, they can be directly re-furnaceed to reduce iron ore mining and energy consumption.

*Wood and Plastics: Waste wood can be processed into recycled boards or biomass fuel; plastics, glass and other recyclables are sorted and re-entered into the circulation industry chain.

*Data reference: Each ton of construction waste can produce about 0.8 tons of recycled aggregate, which is equivalent to saving 0.5 tons of natural sand and gravel mining.

2.Reduce natural resource consumption

Through sorting and recycling, the dependence on native resources such as sand, gravel, metal ore, and wood can be reduced, which is in line with the concept of “waste-free city” construction and circular economy.

二.Environmental protection level

1.Reduce landfill and environmental pollution

*Traditional landfills occupy a large amount of land, and heavy metals (such as lead, cadmium) and residual chemicals in construction waste may penetrate into the soil and groundwater, causing long-term pollution. Sorting can reduce the landfill by 60% to 80%, greatly reducing environmental risks.

*Reduce dust pollution and microbial breeding problems caused by the open-air pileup of construction waste, and improve air quality and surrounding living environment.

2.Reduce greenhouse gas emissions

*Recycled aggregate production can reduce carbon dioxide emissions by about 30% compared to natural aggregate mining (because energy consumption is eliminated from mining and transportation links).

*The energy consumption of metal recycling and smelting is only 10% to 20% of native smelting, significantly reducing carbon emissions.

+8615713843888

+8615713843888

+8615713843888

+8615713843888