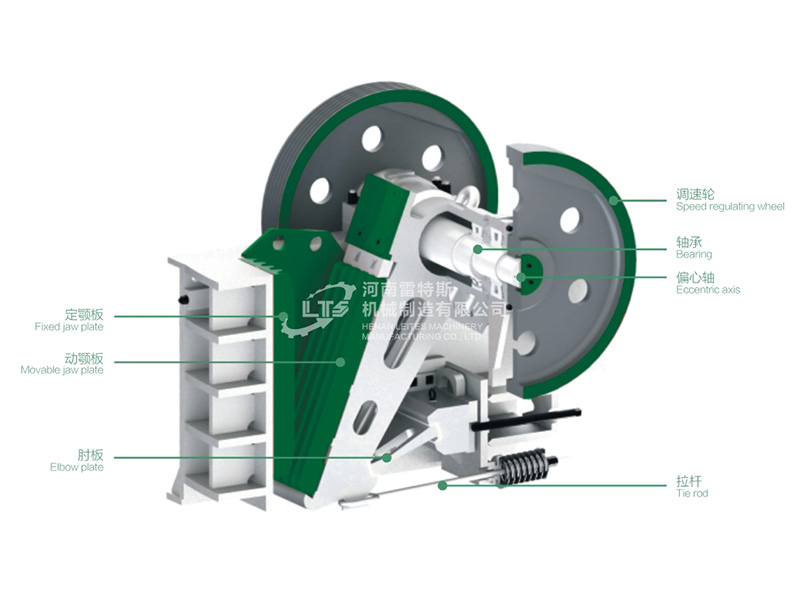

A jaw crusher is a type of crushing equipment used to break large rocks, ores, or minerals. It uses a movable jaw and a fixed jaw to apply compressive force, turning the materials into smaller particles for further processing.

Jaw crushers mainly include a frame, eccentric shaft, large pulley, flywheel, side guards, toggle plate, toggle plate seat, gap-adjusting screw, reset spring, fixed jaw plate, and movable jaw plate. Jaw crushers use a dynamic compression crushing method. During operation, the motor drives the belt and pulley, which makes the movable jaw move up and down via the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and movable jaw increases. This pushes the movable jaw plate closer to the fixed jaw plate. The material is then crushed repeatedly by compression, grinding and squeezing between the two plates. When the movable jaw descends, the angle between the toggle plate and movable jaw decreases. The movable jaw plate moves away from the fixed jaw plate under the pull rod and spring. Crushed material is then discharged freely through the outlet at the bottom of the crushing chamber due to gravity. As the motor rotates continuously, the movable jaw performs periodic crushing and discharging, enabling batch production.

| Model | Incoming material dimensions (mm) | Discharge port size (mm) | Processing capacity (t/h) | Motor power (kw) | Weight (t) | Dimensions (mm) |

| PE1500×1800 | ≤1200 | 210-360 | 520-1100 | 280 | 132 | 7460×6235×4249 |

| PE1200×1500 | ≤1020 | 150-300 | 400-800 | 160-220 | 100.9 | 6380×5310×3710 |

| PE1000×1200 | ≤850 | 200-300 | 280-560 | 110-160 | 69 | 5350×4280×3050 |

| PE900×1200 | ≤750 | 95-165 | 220-450 | 110-132 | 58 | 3800×3166×3045 |

| PE750×1060 | ≤630 | 80-140 | 110-320 | 90-110 | 29 | 2655×2302×3110 |

| PE600×900 | ≤480 | 65-160 | 90-180 | 55-75 | 17 | 2290×2206×2370 |

| PE500×750 | ≤425 | 50-100 | 40-110 | 45-55 | 12 | 2035×1921×2000 |

| PE400×600 | ≤350 | 40-100 | 15-60 | 30-37 | 7 | 1700×1732×1653 |

| PE250×400 | ≤200 | 20-50 | 5-20 | 15 | 3 | 1430×1310×1340 |

| PEX300×1300 | ≤250 | 20-90 | 30-90 | 55-75 | 11.5 | 1750×2320×1724 |

| PEX250×1200 | ≤210 | 25-60 | 20-60 | 37-45 | 8.5 | 2192×1900×1950 |

| PEX250×1000 | ≤210 | 25-60 | 15-50 | 30-37 | 7 | 1550×1964×1380 |

| PEX250×750 | ≤210 | 25-60 | 15-30 | 22-30 | 5 | 1667×1545×1020 |

| PEX150×750 | ≤125 | 18-48 | 5-16 | 15 | 3.8 | 1200×1500×1200 |

| PEX150×250 | ≤125 | 10-40 | 1-3 | 5.5 | 1.5 | 896×745× |

The split welded cast steel frame features a simple structure and strong impact resistance. Heavy-duty eccentric shafts and bearings ensure the moving jaw assembly’s shock resistance. We install heavy-duty protective plates above the movable jaw to withstand strong material impact.

We use high manganese steel for jaw plates and side guard plates, gray cast iron for toggle plates, and high-strength forged steel for eccentric shafts. We subject these components to multiple precision machining, heat treatment, and flaw detection processes to ensure they have sufficient rigidity and strength.

When the device operates, materials exceeding its crushing capacity may enter. These materials can negatively affect the device’s operation and may even damage it. In this case, the toggle plate will break automatically to protect the device from damage.

Gasket-type discharge adjustment devices and centralized lubrication systems simplify operation and maintenance. The jaw plate has a symmetrical structure. It can be reversed after wear, extending service life and cutting replacement costs.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

+8615713843888

+8615713843888

+8615713843888

+8615713843888