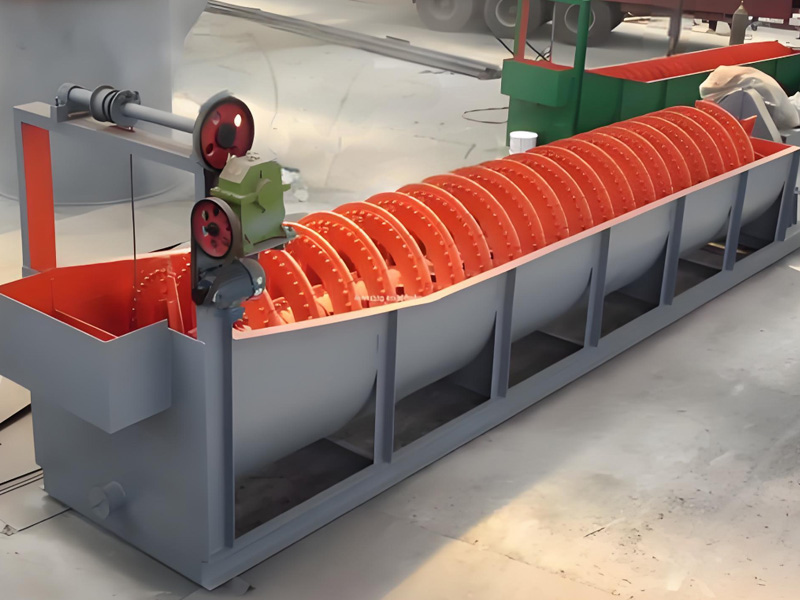

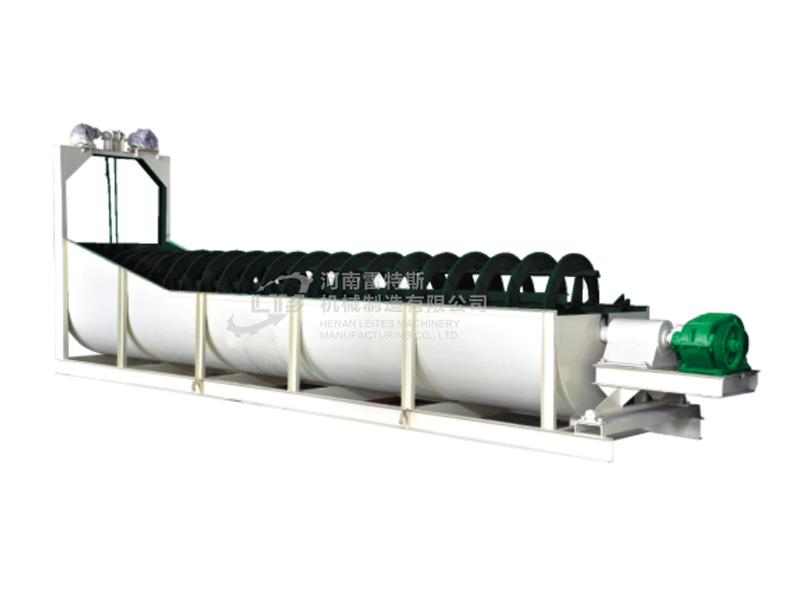

Use: Spiral classifier is widely used for particle size classification of ore slurry in metal beneficiation processes, and can also be used for desliming and dewatering in ore washing operations. It is often combined with ball mills to form a closed-loop process.

Features

Used for the separation of superstandard stone powder in the dry production process of machine-made sand, it can easily control the content of machine-made sand powder and meet the requirements of users .

2, suitable for dry process large, medium sand production line.

3, 0.00–0.75mm stone powder content is adjustable between 2% and 15%.

4, the quality of stone powder is easy to control, the fineness adjustment is convenient, flexible and reliable.

5, tile lining, maintenance rate is very low.

6, the use of frequency control technology, more concise operation.

Working principle

The spiral classifier is based on the principle that the size of solid particles is different, the specific gravity is different, and therefore the settlement rate in the liquid is different [1], the fine ore particles are floating in the water to overflow, and the coarse ore particles are sinking at the bottom of the tank. A grading device for mechanical classification by pushing the screw to the upper part of the discharge, which can grade the ground powder in the mill to filter, and then screw the coarse material into the feed port of the mill using the spiral plate, and discharge the filtered fine material from the overflow pipe. The machine base is made of channel steel, and the body is welded with steel plate. The inlet head and shaft head of the spiral shaft are made of cast iron sleeves, which are wear-resistant and durable, and the lifting device is divided into two kinds: electric and manual.

Applications

- Mineral Processing: Commonly used in the processing of ores such as gold, copper, and iron, where it helps to classify particles before further processing.

- Sand Washing: It can also be utilized in sand washing applications to separate finer sand particles.

Benefits

- Improved Efficiency: By effectively separating particles, the classifier helps enhance the overall efficiency of mineral processing operations.

- Cost-Effective: Its simple design and ease of operation can lead to lower operational costs.

If you have specific questions about its operation, applications, or maintenance, feel free to ask!

+8615713843888

+8615713843888

+8615713843888

+8615713843888