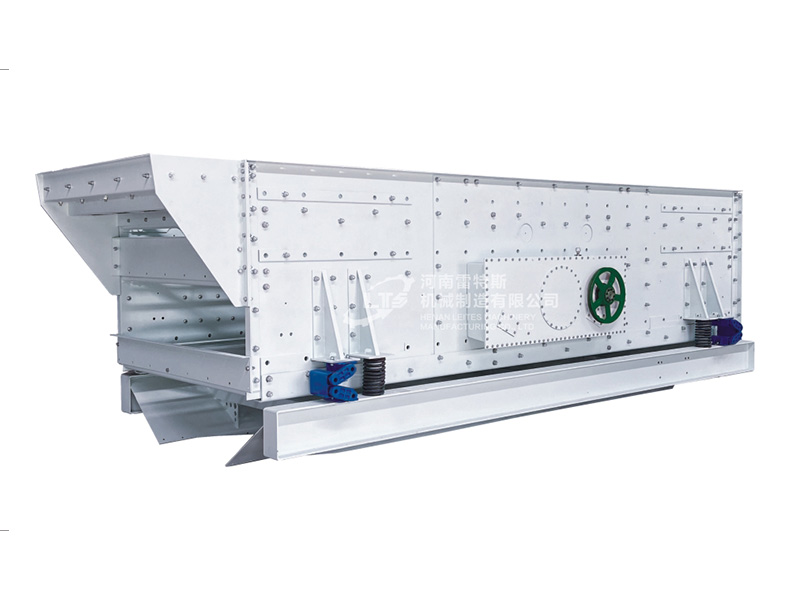

The WZS series horizontal vibrating screen is developed by absorbing similar vibrating screen technologies at home and abroad. Due to its horizontal installation, it occupies a small on-site space and is widely used in industries such as metallurgy, building materials, and transportation. It is an ideal equipment for mobile crushing stations. The three-axis drive can generate ideal elliptical motion in the screening machine, combining the advantages of circular vibrating screen and linear vibrating screen. It has the characteristics of good screening performance, large processing capacity, and small installation height. The vibration trajectory can be selected according to the actual material condition, which is more advantageous for difficult to screen materials. It is an ideal equipment for various mines, quarries, and mobile screening stations.

Widely used in screening operations in various crushing and screening processes; Screening of materials in mining sites and screening of aggregates in crushed asphalt and concrete mixing plants; Utilization of solid waste resources, such as house demolition, recycling and screening of road concrete; Material screening in other industries.

| Model | Maxmum feeding size(mm) |

Double amplitude (mm) |

Vibration freguency(r/min) | Production capacity(t/h) | Motor power(kw) |

| WZS-5 | 150 | 14-18 | 645-875 | 280-350 | 30 |

| WZS-6 | 150 | 14-18 | 645-875 | 350-500 | 37 |

| WZS-10 | 150 | 14-18 | 645-875 | 500-800 | 45 |

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

+8615713843888

+8615713843888

+8615713843888

+8615713843888