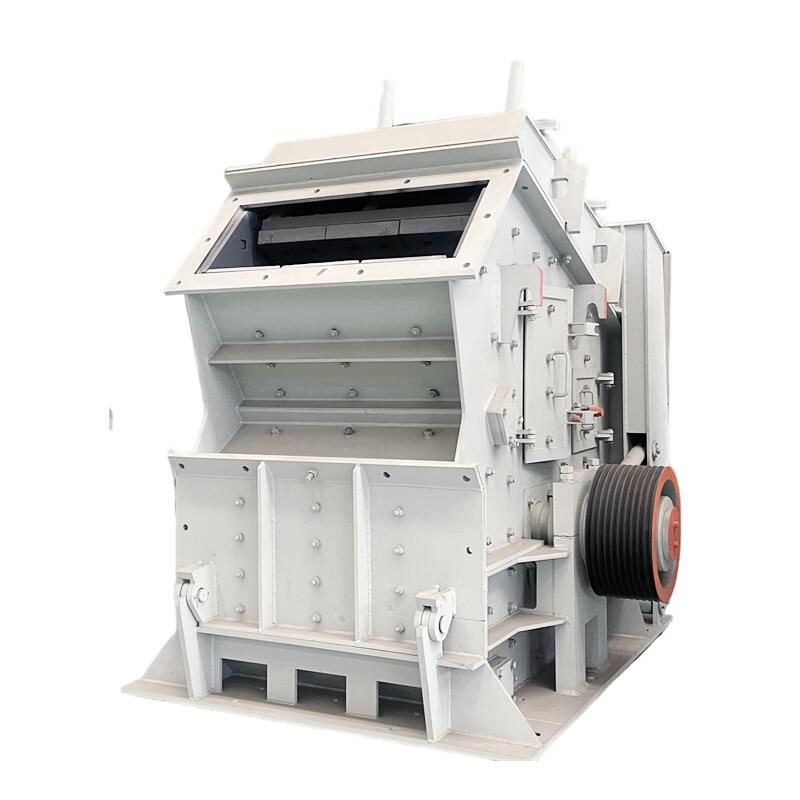

Impact crusher referred to as the impact break, it is mainly used to crush such as building materials, metallurgy, chemical, hydropower, etc., especially the crushing of railways, highways, hydropower projects and other moving stones. The introduction of impact crusher has attracted the attention of users and has been widely used. Why are impact crushers favored by users? What are its advantages? The following will give you a detailed introduction.

Impact crusher

First, the impact crusher treats the wet material more effectively, and effectively prevents the material blockage.

When the water content of the material is too large, the feed chute and the impact plate of the impact crusher can be equipped with a heating device to prevent the bonding of the material. The impact crusher does not need to be equipped with a bottom sieve plate to effectively prevent clogging.

Second, the impact crusher is suitable for a wider range of material hardness

The plate hammer of the impact crusher is firmly fixed on the rotor by mechanical clamping structure, and has a great moment of inertia when rotating with the rotor. Compared with the hammer crusher (the hammer head is in a overhanging state), the rotor of the impact crusher has a large momentum, which is suitable for crushing relatively hard materials.

Third, it can easily and flexibly adjust the discharge particle size, and the adjustment range is wide

There are many ways to adjust the discharge size of the impact crusher, such as adjusting the rotor speed, adjusting the gap between the impact plate and the grinding chamber.

Fourth, the wear of wearing parts is small, the metal utilization rate is high

The wear of the impact crusher’s plate hammer only appears on the side facing the material. When the rotor speed is normal, the feed will fall to the surface of the plate hammer (hitting surface), and the back and side of the plate hammer will not be worn. Even the side facing the m

+8615713843888

+8615713843888

+8615713843888

+8615713843888