Ore crusher, also known as the ore crusher, mainly for all kinds of ore crushing treatment, high efficiency, convenient operation, intelligent environmental protection, often used in basic construction, metallurgy, chemistry and iron (road) and other engineering fields, equipment according to the output is different, divided into large, medium and small, which large ore crusher how much? The following will give you a detailed introduction.

First, what are the large ore crusher?

Ore refers to a collection of minerals from which useful components can be extracted or which itself has a certain performance that can be used, which can be divided into metal minerals, non-metallic minerals, such as iron ore, gold ore, hematite, fluorite ore, etc., the characteristics and hardness are different, and the current ore crusher equipment is classified more, complete models, commonly used jaw crusher, cone crusher, heavy hammer crusher, etc. The specific choice of which, combined with actual production needs to choose

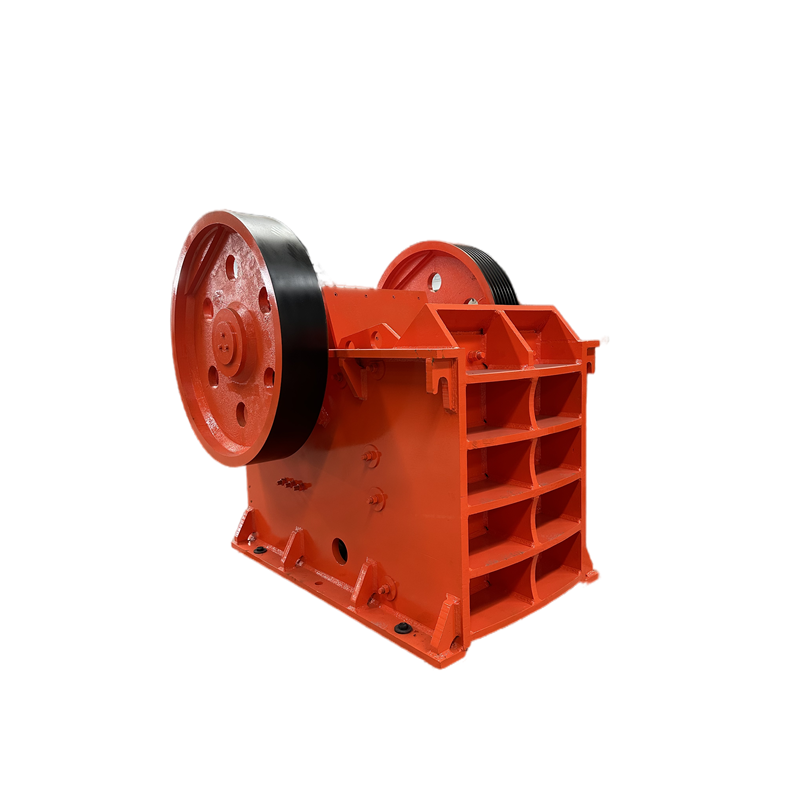

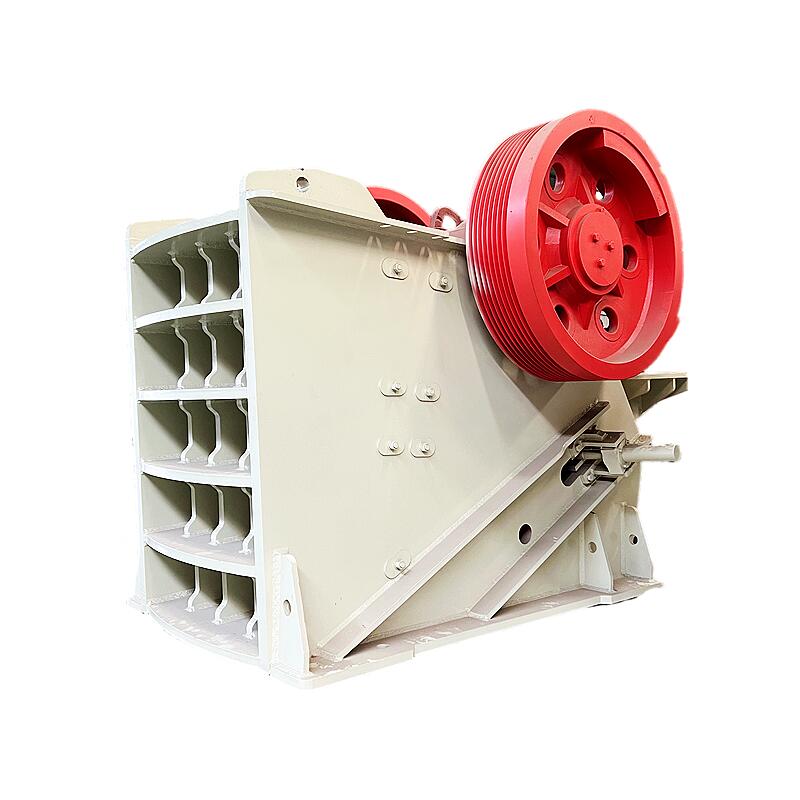

1, jaw crusher

Suitable for all kinds of hardness large ore, with coarse crushing and fine crushing equipment, the working principle of extrusion crushing, optimize the movement parameters, so that the material can start crushing in the upper part of the crushing chamber, the lower stroke is large, the crushing ratio is large, and the wedge is used to adjust the discharge port, the finished product particle size can be adjusted, the particle size is uniform, in addition, at the same time, the motor base and the host integrated structure, The installation is easy and the space is saved.

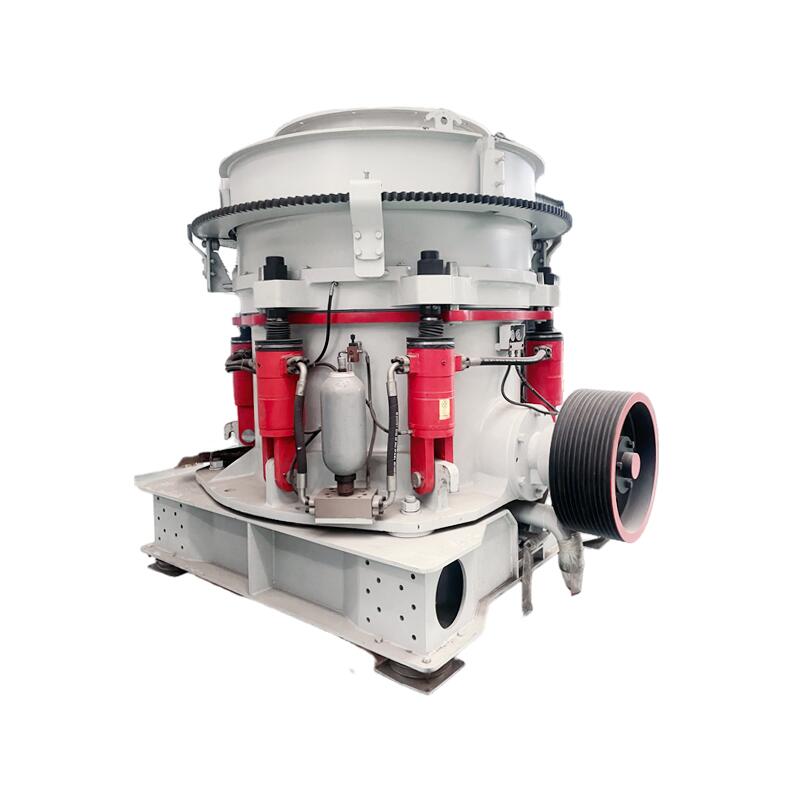

2, cone crusher

Suitable for medium and high hardness ore, single cylinder, multi-cylinder, full hydraulic series, new crusher structure, optimized laminated crushing chamber type and intelligent automatic control system and innovative Internet control system, large production capacity, low energy consumption, and large eccentrics and high swing frequency design, can make the equipment run at a lower speed, can change the product grading to produce less fine material, All components of the host can be removed from the upper or side assembly, making the operation convenient and low maintenance cost.

3, heavy hammer crusher

Suitable for medium hardness and brittle ore, can be broken wet material, through the adjustable adjustable lining plate and material flow trough design, to achieve impact crushing, counter-shaping, self-discharge material, change the two-stage crushing into a primary crushing, coarse, medium and fine crushing free conversion, reduce the process flow, increase the amount of work, no grate design, adjustable discharge particle size, flow trough design, to avoid repeated crushing, The powder production is small, and the large machine is equipped with hydraulic hammer shaft device, which is convenient to replace the hammer head and hammer shaft, saving time and labor.

Second, how much is a large ore crusher?

For large ore crusher prices, from the market point of view, usually in the hundreds of thousands to millions of yuan, showing differentiation, because of different equipment types, models, the parameters are slightly different, mainly to see how to choose, plus more manufacturing and sales enterprises, so the market quotation is only for reference.

Leitos machinery As a large mining machinery and equipment manufacturers and suppliers, has a wealth of crusher manufacturing experience, machine quality is good, high efficiency, complete variety, in the market is very popular with investors, if you want to know more about the crusher information, welcome to call or online consultation, message, Leitos machinery will send professionals to answer your questions

+8615713843888

+8615713843888

+8615713843888

+8615713843888