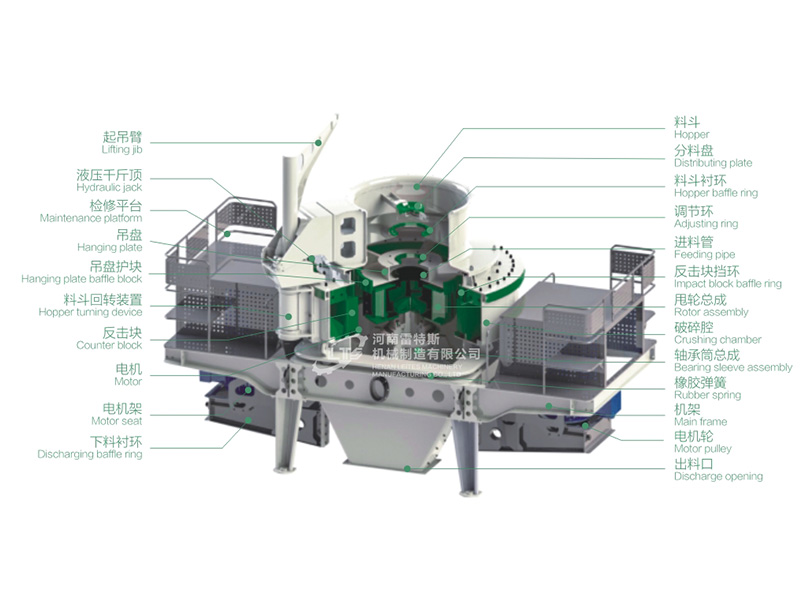

The 5X series high-efficiency centrifugal impact crusher is an advanced technology introduced by our company from Germany. It is a perfect combination of professional crushing technology and mechanical manufacturing, and a full embodiment of new technologies and processes. It not only provides the highest quality sand and gravel aggregates for highways, high-speed railways, high-rise buildings, municipal engineering, hydropower dam construction, port terminals, concrete mixing plants, etc. It has become an undisputed core equipment in the mechanism sand industry and stone shaping field, but is also increasingly becoming the mainstream equipment in the fields of metal ore crushing, quartz sand production, and steel slag processing.

It has uniqve characterstics and advantages:

1. Deep cavity type rotor go through optimized design, can increase the materials thruput by about 30%

2, After around backplate has local wear, users can tum around up and down to use, to improve the

malecalutizalon and mooue the sence le mre 48%, wea esian hick omhoed hoe usi meedto edac he wom nats which can redue he us-cosl oer 3

3. The core wear-resisting material use highly wear resistant and high temperalure resistant malenal used in the U.S. important industry.

4, Use dlamond impact block, to avoid damage vertical plate after materlals impact and wear.

5. The optimal launch pot and interir smoolh curvinear design, reducng the fow resistance ofthe malena, and grealy improving the malenal through capacly.

6, Dual-use bulk trays, simple operation, easy canversian to achieve two feeding method.

7. On the bottom of the spindle, speclal sealing siructure can ensure that no al seal or not leaking.

8. Usng imported wih ongnal packaging parts hydrauc openings device can coenien and quchy move loam cake,to repace and maintenance the body’s intemal parts win orowcial labor.

9. Select and use high level proleclion molor, This molor has hgh elicency, bow nose eic,in ine wih the iniemaonalFlecirolechcal Commission lEc slandar. F class insulation and iP54,55 protection leve!

| Model | 5X7615 | 5X8522 | 5X9532 | 5X1145 | 6X1150 | 6X1263 |

| Waterfall andcenter feeding | 150-280 | 240-380 | 350-540 | 500-640 | 550-745 | 650-850 |

| Whole center feed | 70-140 | 120-200 | 180-280 | 250-640 | 344-368 | 454-486 |

| Optmal feed size(Soft) | 35 | 40 | 45 | 50 | 55 | 60 |

| Optmal feed size(Hard) | 30 | 35 | 40 | 45 | 45 | 50 |

| Rotaing speed(r/min) | 1710-1900 | 1530-1700 | 1380-1550 | 1200-1390 | 1000-1300 | 900-1200 |

| Dual motor power(kw) | 75×2 | 110×2 | 160×2 | 220×2 | 250×2 | 315×2 |

| Dimensions(mm) | 4100x2330x2300 | 4140x2500x2700 | 4560x2600x2900 | 5100x2790x3320 | 5500x2750x3950 | 5700x2980x4190 |

| Power supply | 380v,50Hz | |||||

| Dual oil pump motor power | 2×0.25KW | |||||

| Safety protection | Dual oil pump complementary fuel supply; Automatic shutdown without oil flow; Air-cooled cooling; Winter motor heating start | |||||

| Power of oil tank heater | 2KW | |||||

| Dimensions(mm) | 820x520x1270 | |||||

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.

+8615713843888

+8615713843888

+8615713843888

+8615713843888